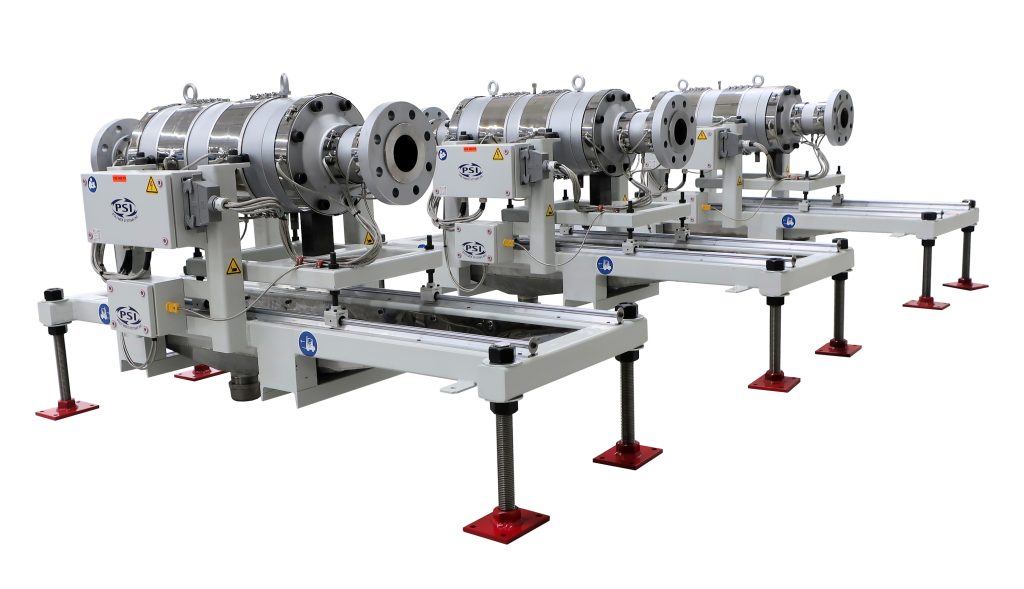

In-Line Filter Extended-Area (ILF-EA)

Get More from Your Process

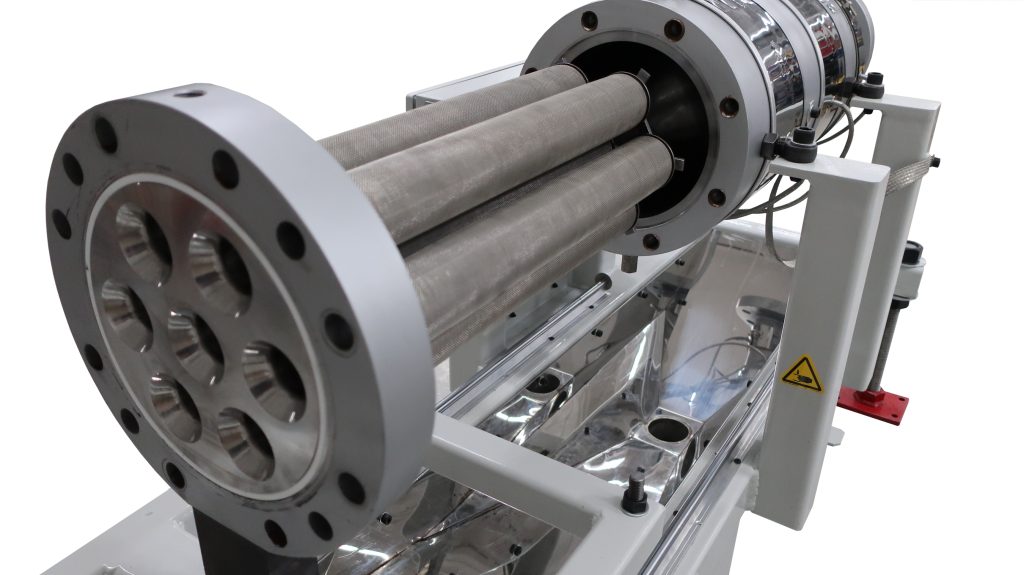

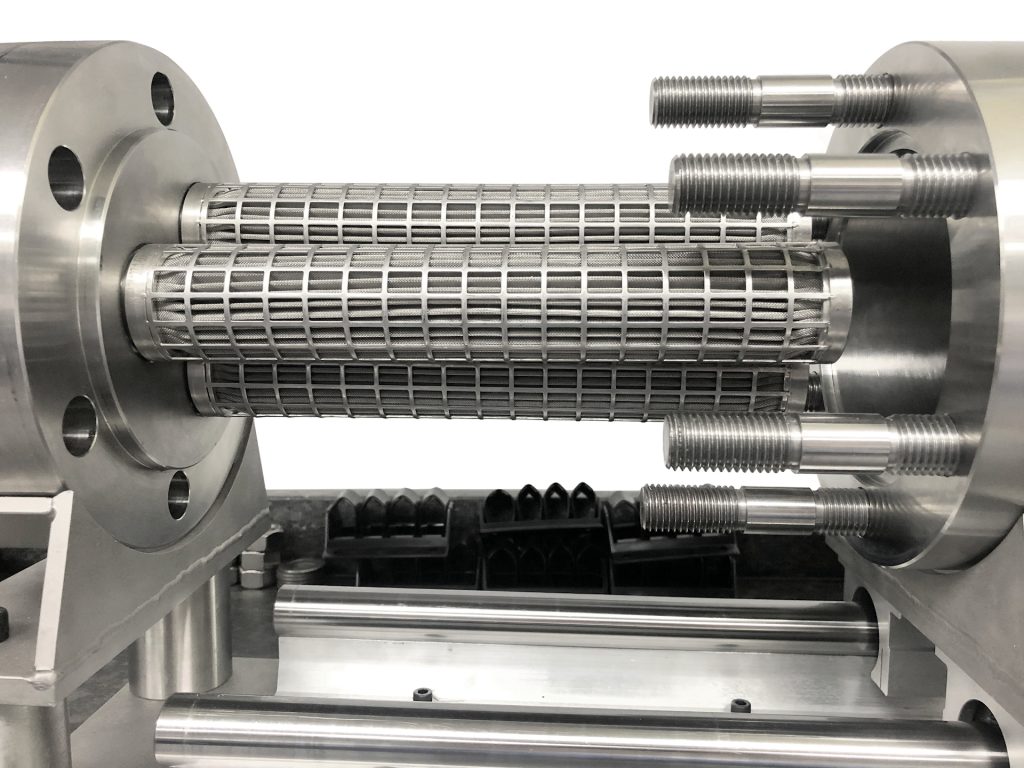

In-line Filters – Extended-area (ILF-EA) are supplied for monomer, pre-polymer or polymer filtering systems. Utilized in long batch runs where the process cannot be disturbed, ILF filters remove impurities including gels and solid particulates requiring fine micron level filtration. Optimal filter area and media type are selected according to your application-specific particle size, pressure, flow and temperature requirements. The design stabilizes melt velocity in the vessel and eliminates gel formation using a multi-port discharge bushing. This bushing blends the flow of the filter exit ports into a single stream closely matching the cross-sectional area of the vessel exit bore.

Specifications

| Element | Filter Area | |||||||

| Model | Diameter | Length | Cylinder | Pleat | ||||

| in | mm | in | mm | in² | cm² | in² Approx. | cm² Approx. | |

| ILF-40x3 | 2 | 50.8 | 6 | 152.4 | 113.1 | 730 | 360 | 2330 |

| ILF-75x3 | 2 | 50.8 | 12 | 304.8 | 226.2 | 1459 | 725 | 4670 |

| ILF-150x3 | 2 | 50.8 | 24 | 509.6 | 452.4 | 2919 | 1450 | 9340 |

| ILF-225x3 | 2 | 50.8 | 36 | 914.4 | 678.6 | 4378 | 2170 | 14000 |

| Element | Filter Area | |||||||

| Model | Diameter | Length | Cylinder | Pleat | ||||

| in | cm | in | cm | in² | cm² | in² | cm² | |

| ILF-40x7 | 2.36 | 6 | 5 | 12.7 | 259.7 | 1675 | 831.2 | 5362 |

| ILF-75x7 | 2.36 | 6 | 10 | 25.4 | 519.5 | 3351 | 1662.3 | 10724 |

| ILF-150x7 | 2.36 | 6 | 20 | 50.8 | 1039.0 | 6703 | 3324.6 | 21448 |

| ILF-225x7 | 2.36 | 6 | 30 | 76.2 | 1558.4 | 10054 | 4987.0 | 32174 |

| ILF-300x7 | 2.36 | 6 | 40 | 101.6 | 2077.9 | 13405 | 6649.3 | 42898 |

Features

- Repeated cleaning and long term uses.

- Suitable for high temperature and corrosive material applications.

- High level of purity

- Long production runs between filter changes

- Improved end-product

- Reduced inclusions

- Improved process stability

- Improved film tear resistance

Options

- Horizontal or vertical ILF configurations are available

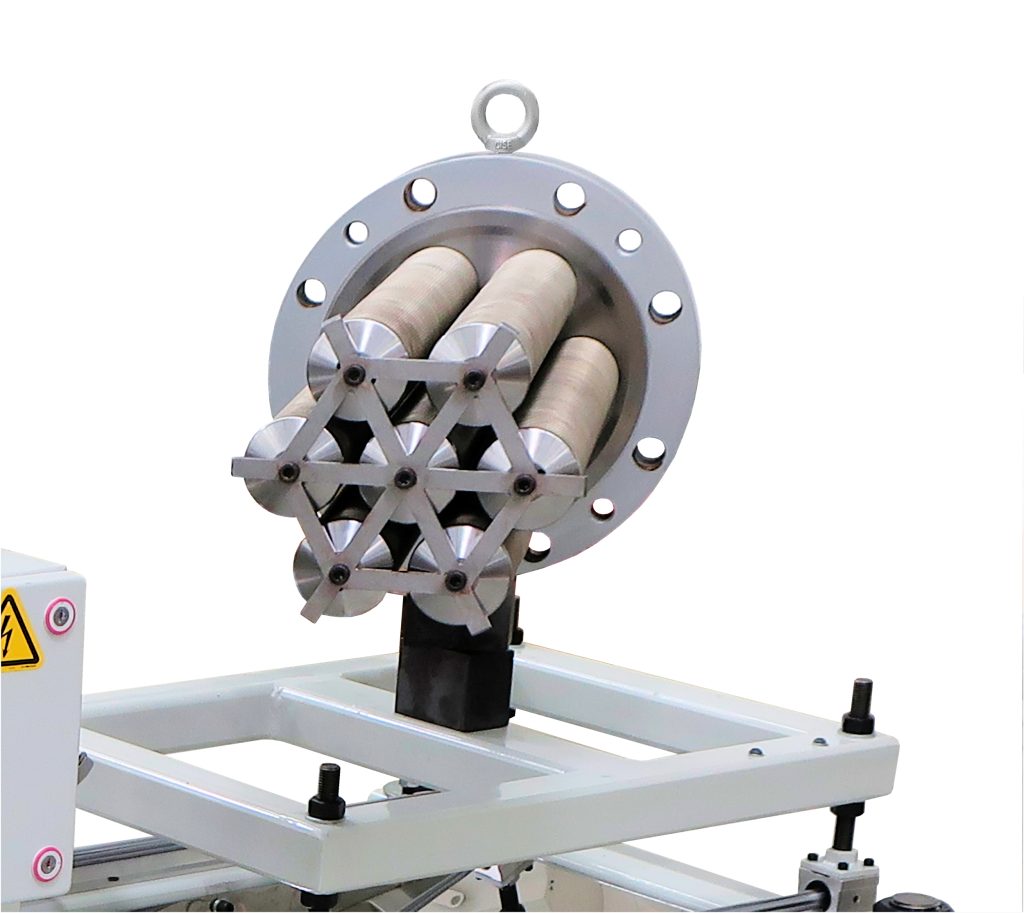

- Filters: Cylindrical tube, pleated tube, leaf (disk pack)

- Media: Wire cloth or sintered

- Quick-disconnect heater plugs

- Instrument ports

- Air bleed valve to eliminate air at start-up

- Insulation jacket

- Pre-heat station (for electric version)

- Heat control panel

- Y-block valves for dual filter systems

- Custom engineering

Construction

- Vessel: 304 or 316 Stainless Steel

- Filter tubes (for cylindrical filters): 17-4 Stainless Steel

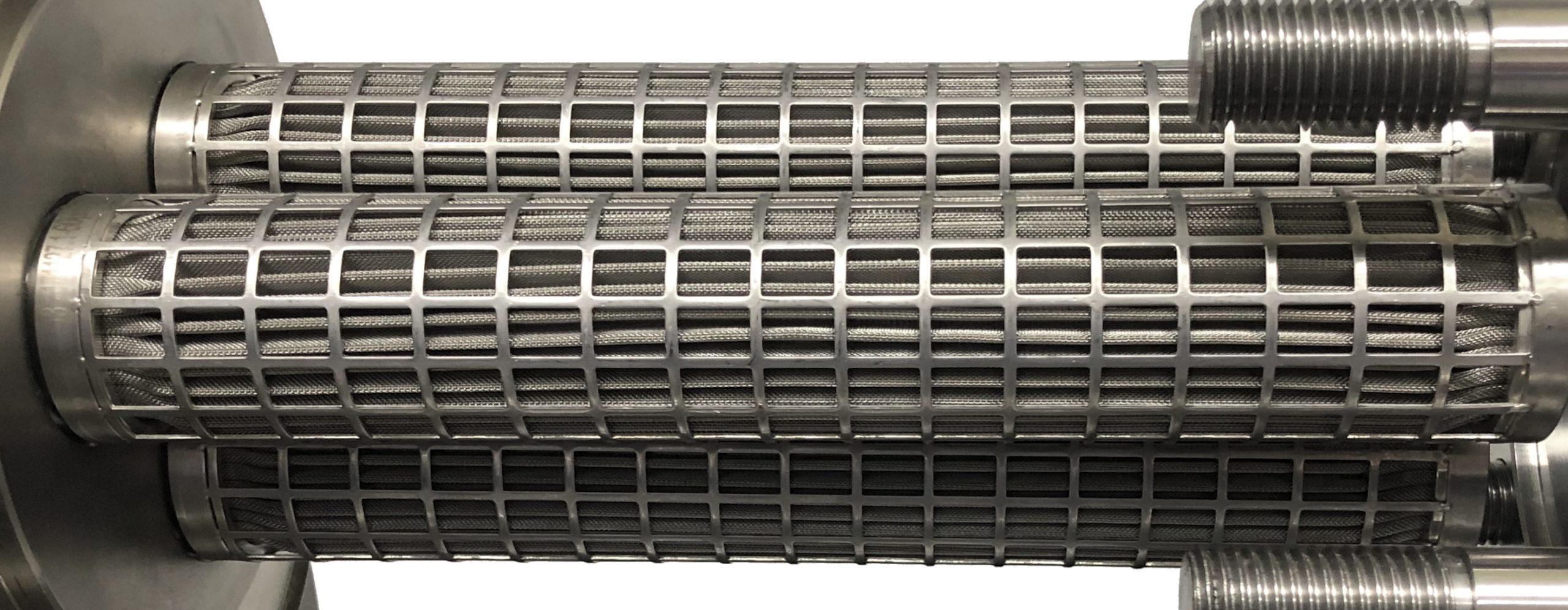

Cylinder vs. Pleat Filter Media

Cylinder

- Withstands high pressure drop with breaker plate tube support

- Low cost, disposable media

- Broad availability

Pleat

- Typically offer 3 times the area of a cylinder for longer runtimes.

- Can be cleaned and reused up to 20 times

- Pressure drop limited

- Requires specialized cleaning procedure