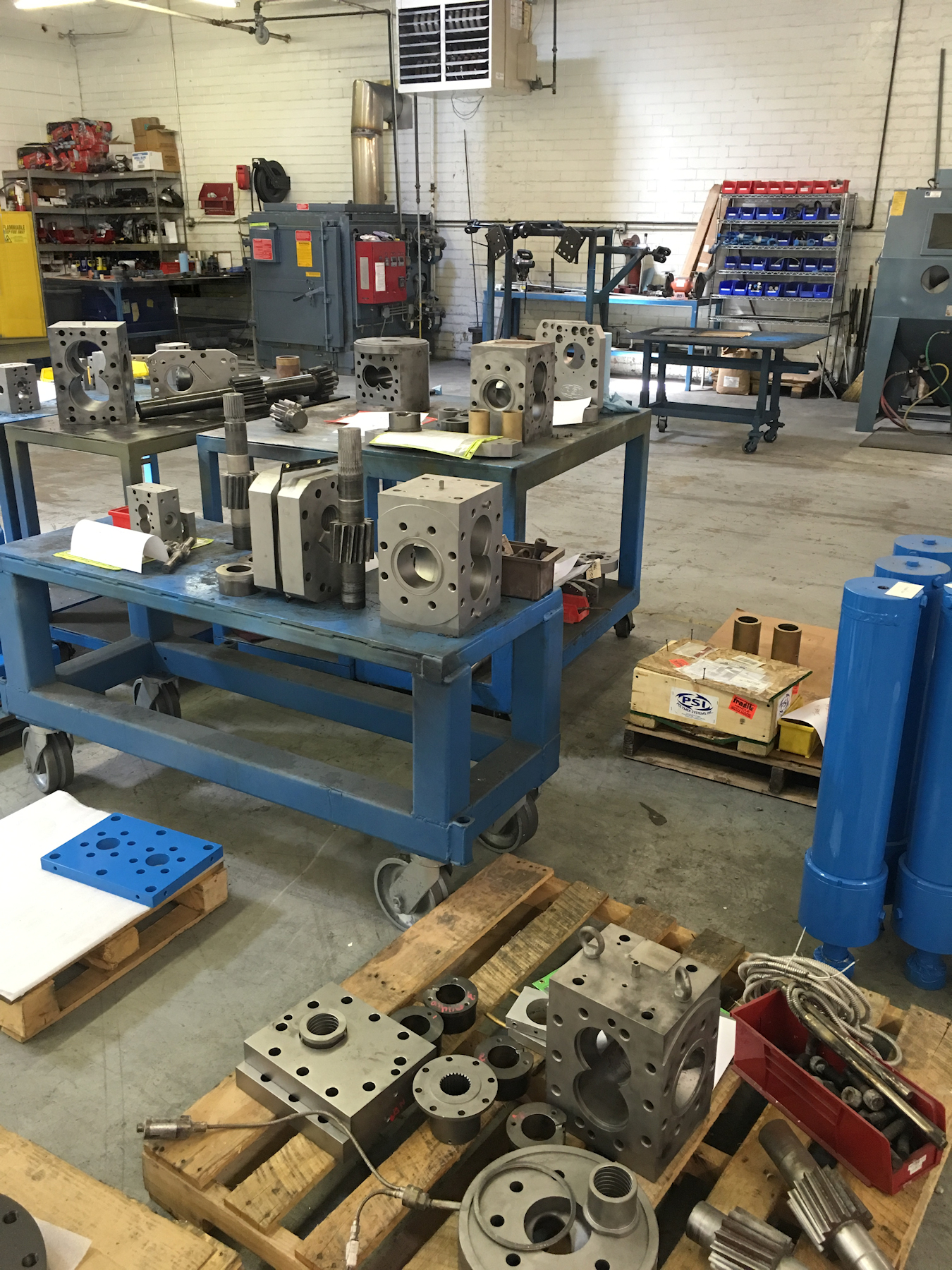

Rebuilds and Repairs

Bring us your parts and pieces and breathe new life into your old equipment!

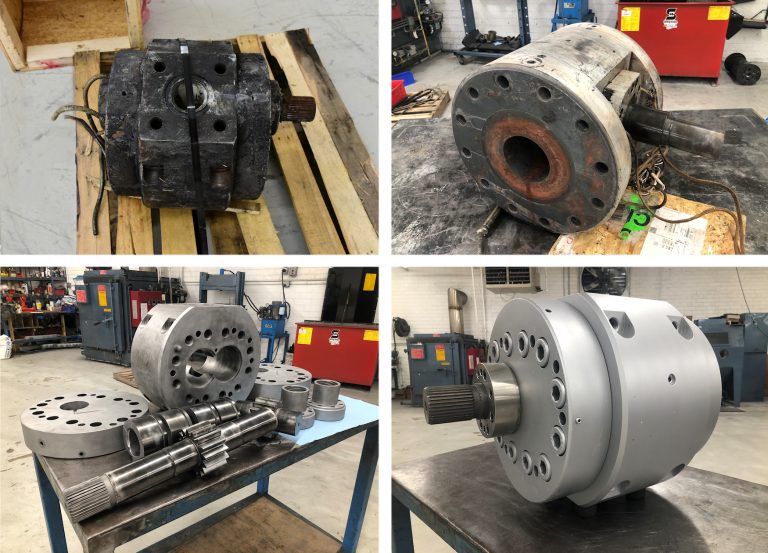

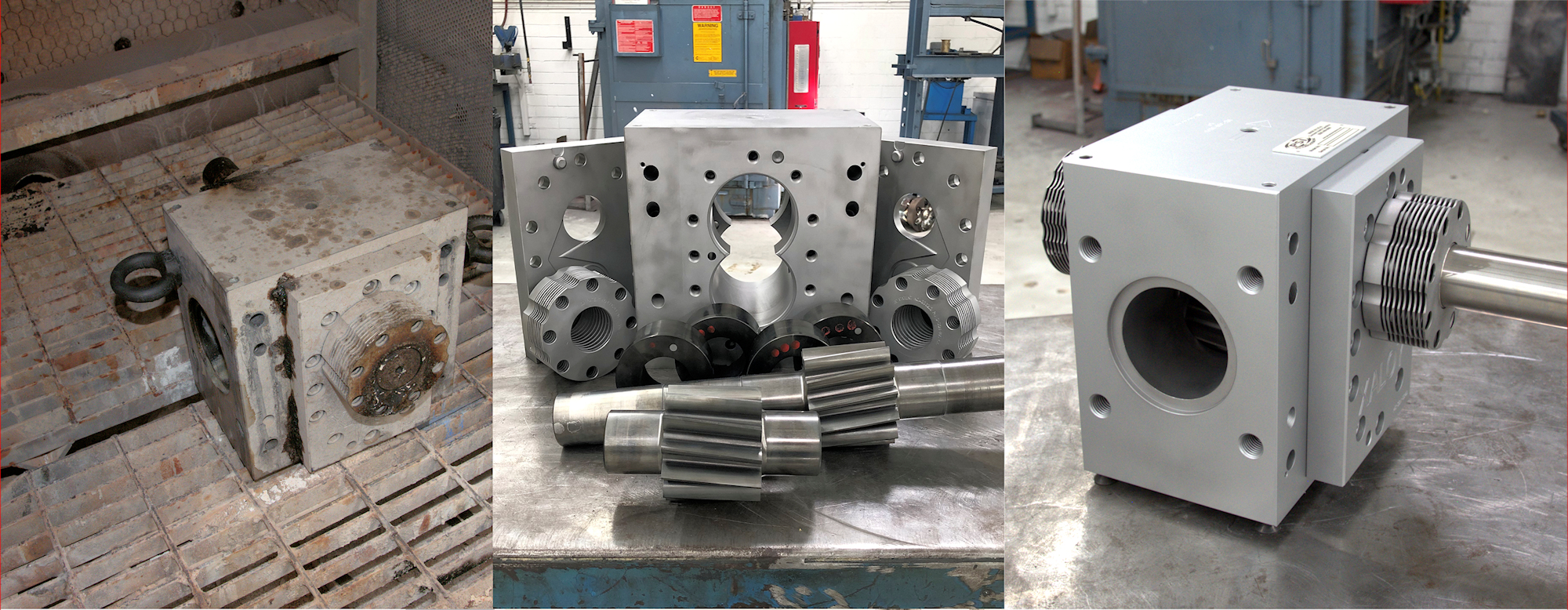

Rebuilds present a great environmentally sound and sustainable cradle-to-cradle solution. This cost-effective option saves having to discard equipment that has reached the end of its service life. Several options are available; from simple evaluations to part replacement to complete overhaul and restoration.

PSI operates a complete in-house repair center capable of rebuilding most major brands of gear pumps, bolt-type screen changers, and static mixers.

- Burn out and cleaning available

- Precision measuring of each part

- Gauging traceable to NIST standards

- We carry internal parts to fit most major melt pump brands

- Custom parts and machine work available

- Weld repair on screen changer cross-bolts and housings and on larger gear pump housings

- Maag

- Kreyenborg

- Nordson/Xaloy

- Normag

- Erema

- Witte

- Others

Example: Dynisco HSC-80 (Click for images)

Example: Beringer SPC-1200 (12″) (Click for images)

Restore machine efficiency and performance to original OEM specifications!

Call us 1-828-468-2600 or email service@psi-polymersystems.com and ask for Jody to schedule a rebuild during your next planned line maintenance.

Trade-Ins

Ask about our Screen Changer trade-in program as well!

Is your pump costing you production efficiency? Are repetitive repairs are no longer cost-effective?

Trade it in! PSI will offer you a far greater trade-in value than you will find on the used equipment market. PSI pumps are drop-in replacements for most of our competitors. Give us a call and you will be pleasantly surprised at how easy, cost-effective and fast a PSI gear pump can be made to swap out your tired old relic.

Plus You’ll Receive…

- Service with a smile

- Longer lasting gears

- Trouble-free seals

- More accurate gauge control

- Increased output rates

- Faster start-ups

- Lower processing temperatures

- Reduced scrap

- Increased life for the extruder screw and barrel