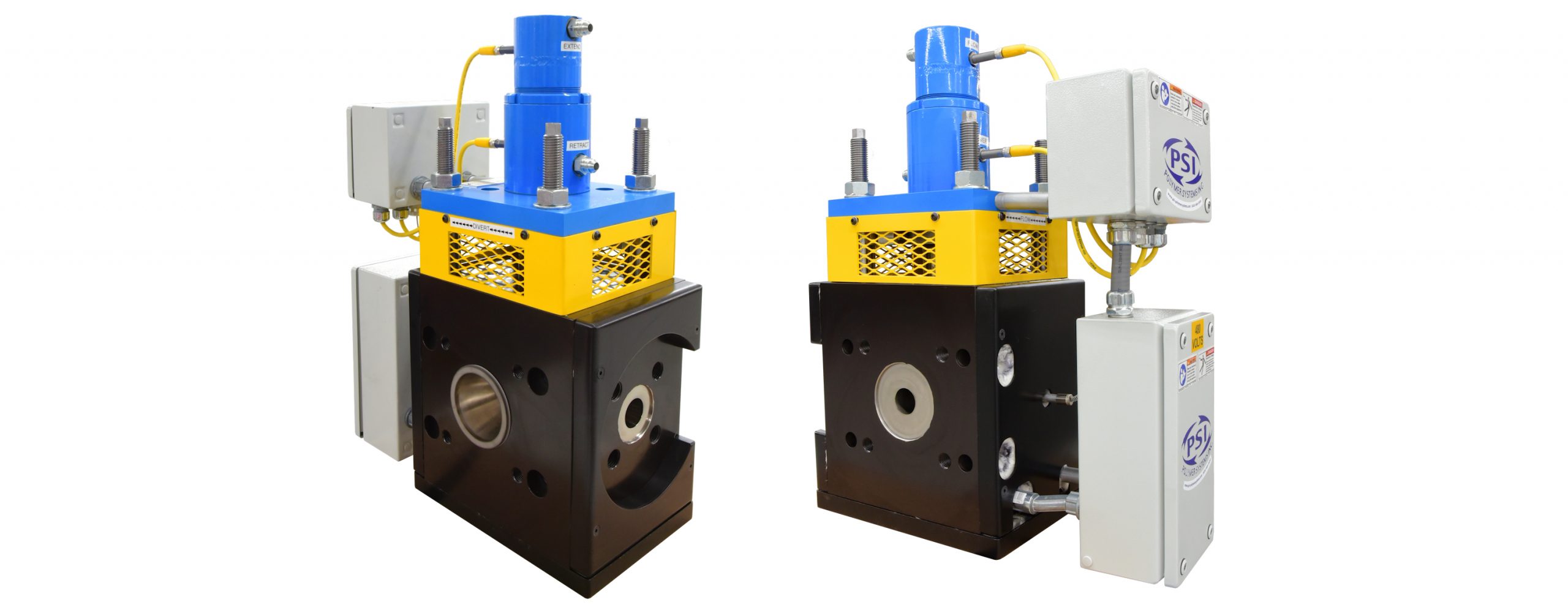

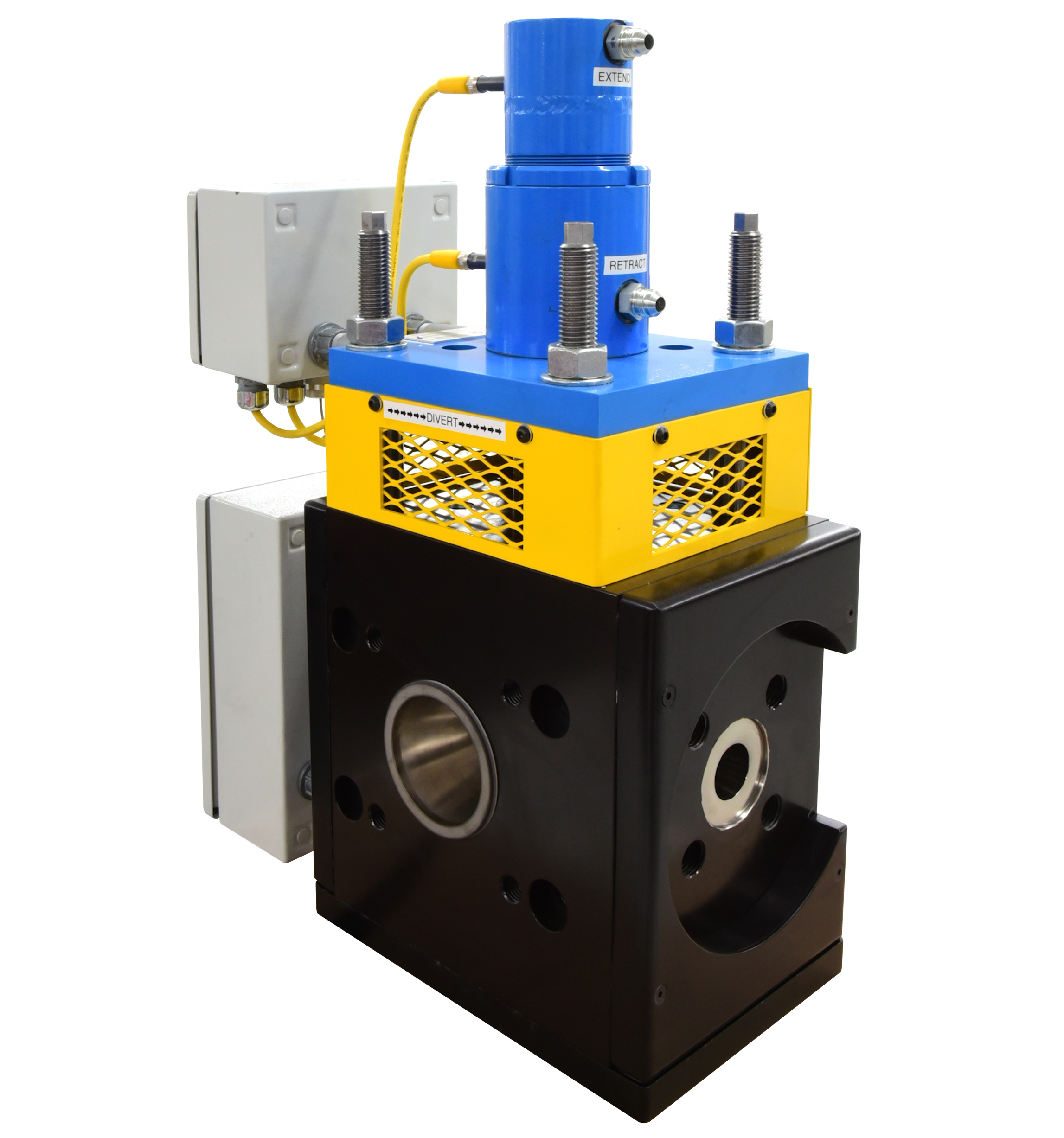

Diverter Valve (DIV)

Get More from Your Process

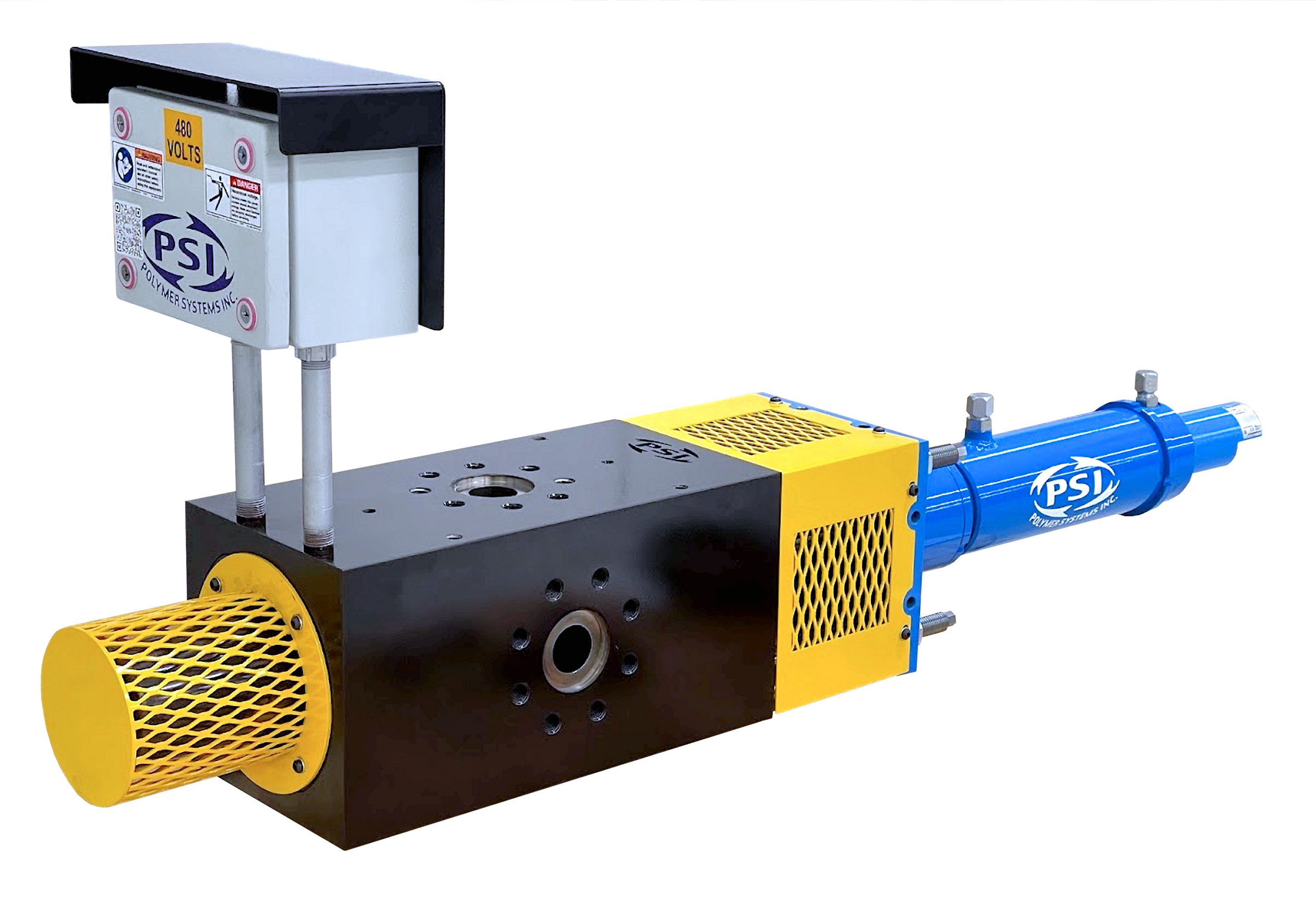

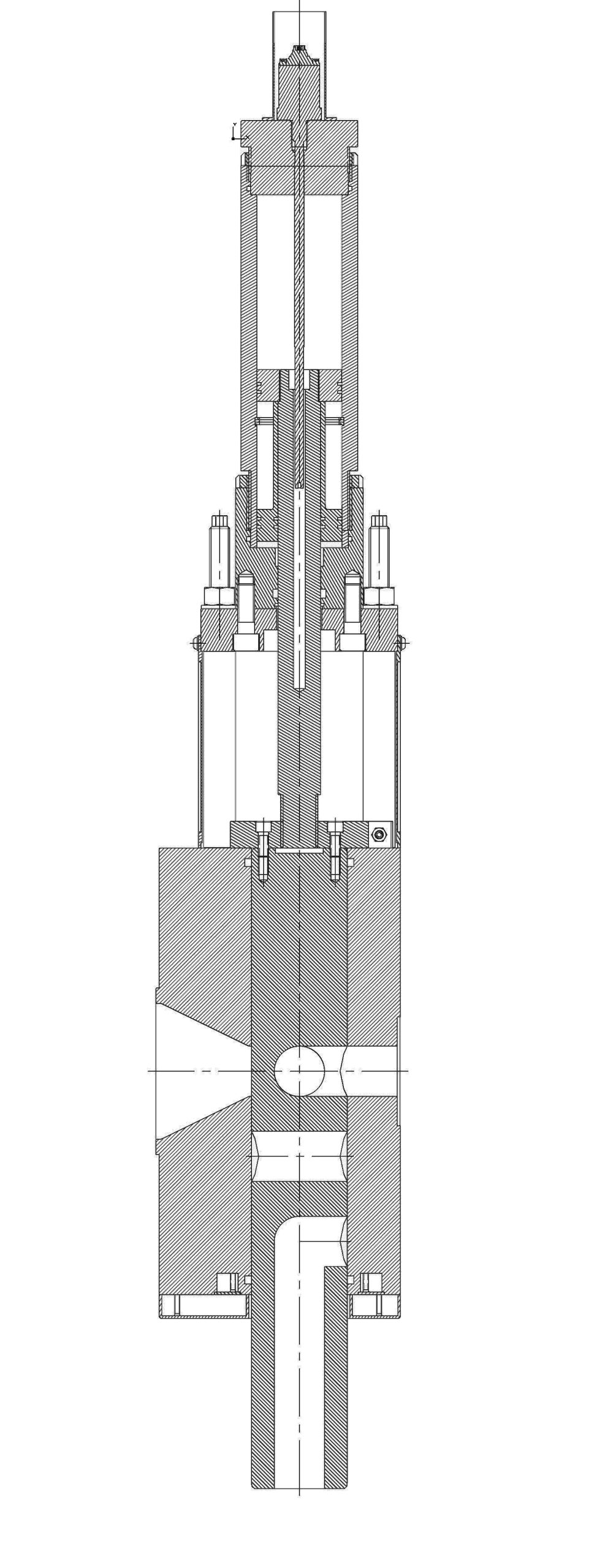

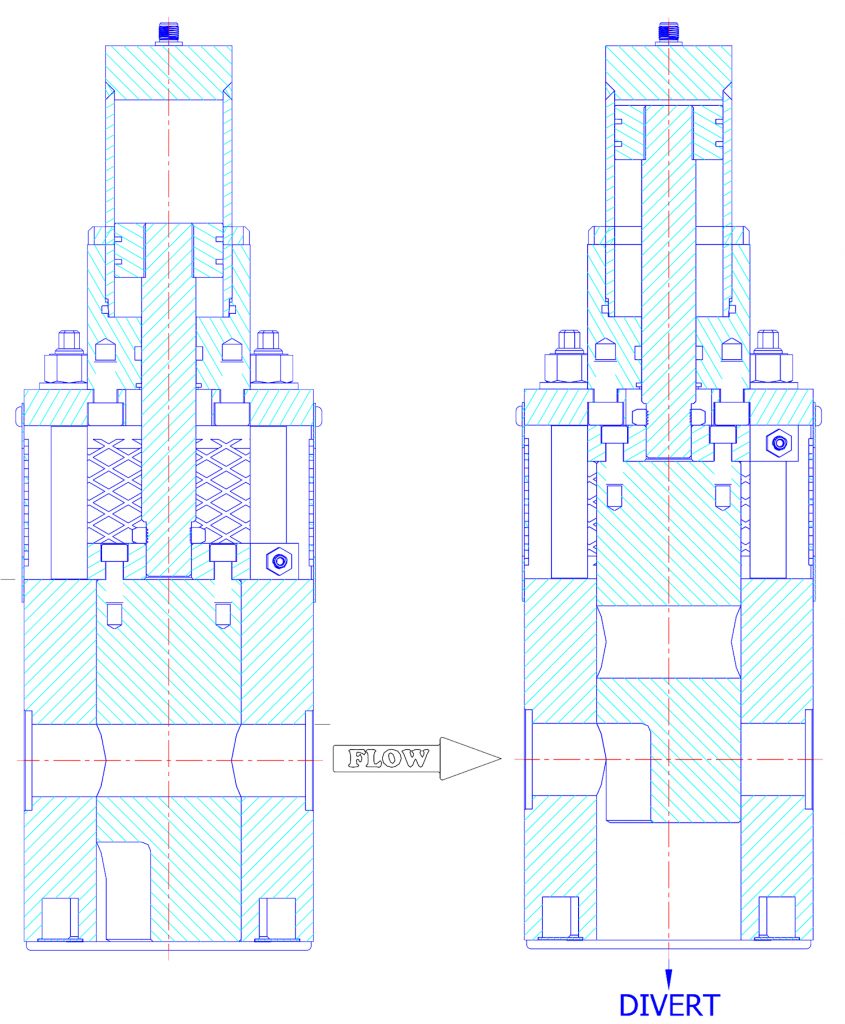

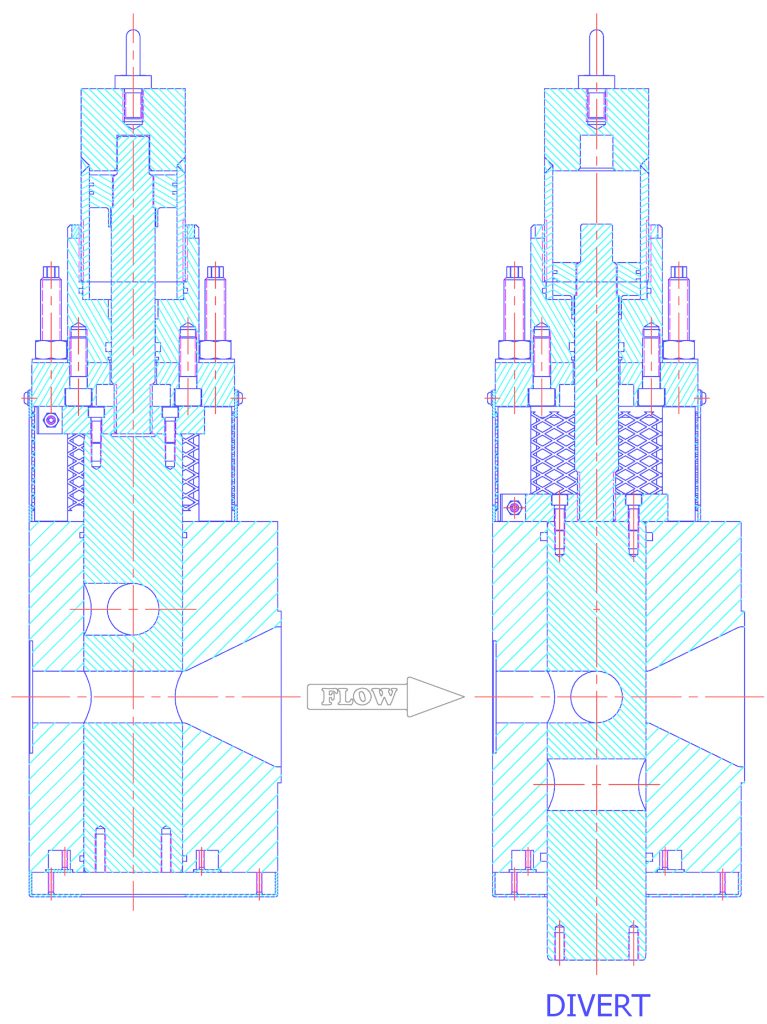

PSI Diverter Valves (DIV) direct the flow of a fluidized material stream to a selectable destination. Used in polymer, hot melt adhesive, food, and chemical applications, diverter valves are commonly supplied in a two-position (process/dump) configuration to facilitate start-up, drum-fill operations, or redirection to a secondary process. For pelletizing operations, the dump position segregates start-up materials, including off-spec generated during crossover for material or color changes. Once the material flow and quality are fully established, a quick shift to the online position assures optimal pressure and flow to the die. For drum or vessel fill operations, the dump position is used for bypass.

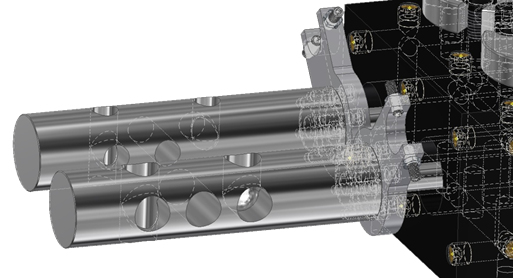

Multiple (three or four) position diverter valves add bypass and multi-directional flow functionality. Applications for these include alternating die and simultaneous multi-die flow as well as bypass or tank fill. Discharge ports can be configured to accommodate virtually any direction. These diverter valves offer vertical and rotational port movement. Sizes range from small batch operations to large polymer reactors requiring continuous output.

Specifications

| Temperature °F [°C] | Up to 650 [343] |

| Max oper. pressure PSI [bar] | max. 10,000 [670] |

| Control zones (housing) | One (1) |

| Heating | Electric/Fluid |

| Max. Throughput¹ | Through-bore Diam. | Divert Position² | Weight | ||||||

| Model | Lbs/Hr | Kg/Hr | inch | mm | Zones | kW | Lb | Kg | |

| DIV-1.0 | 1,250 | 5,67 | 1.00 | 25.4 | Bottom | 1 | 3.0 | 105 | 48 |

| DIV-1.5 | 2,500 | 1,134 | 1.50 | 38.1 | Bottom | 1 | 4.0 | 185 | 84 |

| DIV-2.0 | 4,500 | 2,042 | 2.00 | 50.8 | Bottom | 1 | 4.0 | 222 | 101 |

| DIV-3.0 | 10,000 | 4,536 | 3.00 | 76.2 | Bottom | 1 | 6.0 | 300 | 137 |

| DIV-4.0 | 18,000 | 8,165 | 4.00 | 101.6 | Bottom | 1 | 12.0 | 550 | 250 |

| DIV-6.0 | 40,000 | 18,144 | 6.00 | 152.4 | Bottom | 1 | oil/steam | 2,650 | 1,202 |

| DIV-8.0 | 75,000 | 34,020 | 8.00 | 203.2 | Bottom | 1 | oil/steam | 3,550 | 1,610 |

| PDV-6 | 2150 | 975 | 1.38 | 35.0 | Side | 1 | 6.0 | 396 | 180 |

| PDV-7 | 6,250 | 2,835 | 2.36 | 60.0 | Side | 1 | 6.0 | 797 | 362 |

| ¹Throughput values may change depending on material, viscosity and filtration level. ²Multi-port models will divert to customer defined positions. Consult factory for information. ³Shift times can be faster or slower according to user specified process requirement. | |||||||||

Features

- Approx. one (1) second shift – process specific

- Bolt-on connection (DIV models)

- Bolt-though housing eliminates upstream adaptor for less residence time (PDV models)

- Conical discharge for underwater pelletizer nose cone connection (PDV models)

- Side or bottom discharge

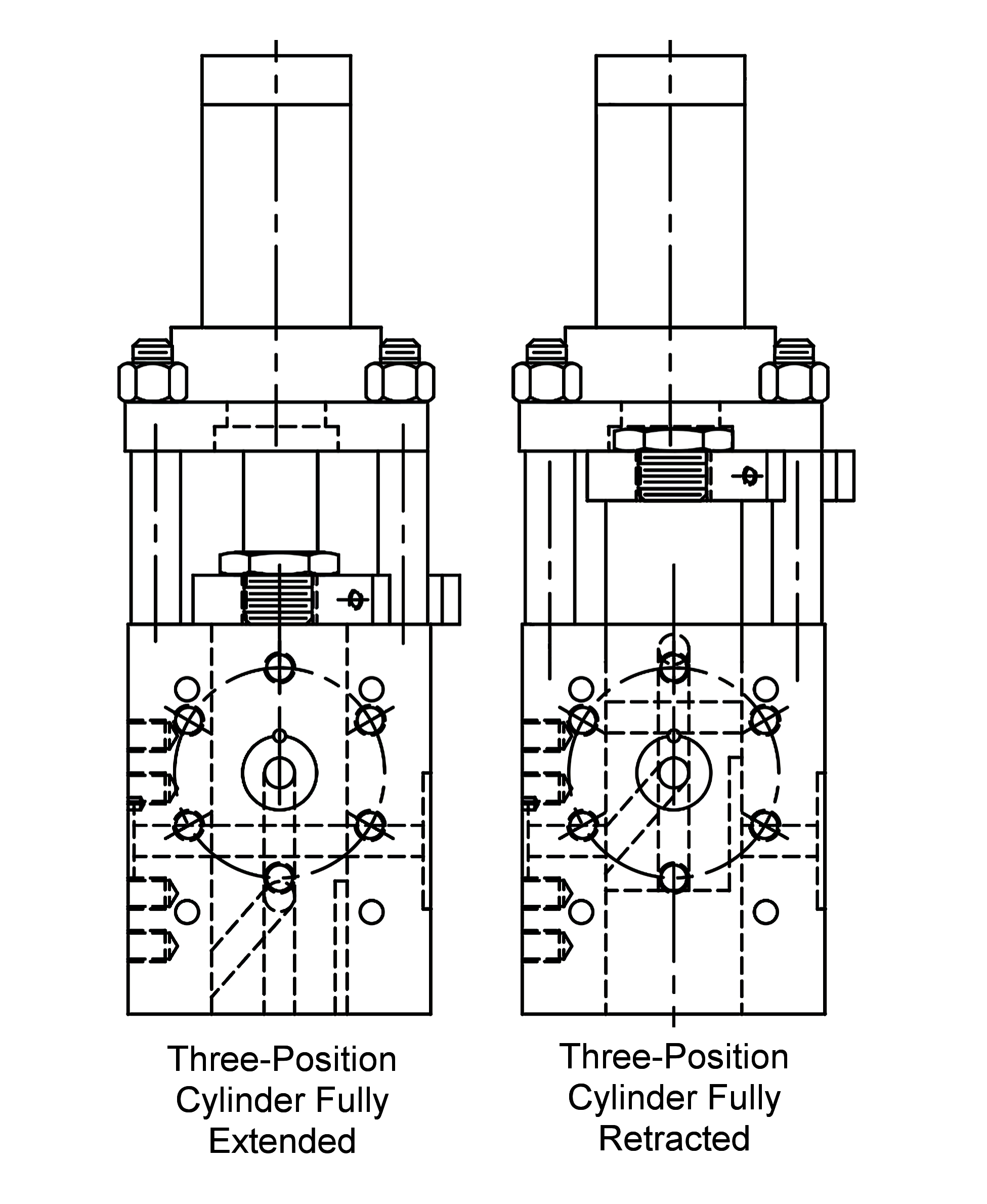

- Hydraulic divert actuation

- No mechanical seal cross-bolt design – 5-year leak-free guarantee

- Stainless steel discharge chute (for side discharge models)

- Mechanical stop for accurate positioning

- Large, robust hydraulic cylinder for added shift assurance

- Low residence time

- Safety guard with electrical interlock

Options

- Patented seal system for low viscosity / high MFI materials

- Proximity sensors for position indication

- Integral pressure/temperature ports

- Stainless steel construction

- Internal fluid heat/cool

- Insulation jackets

- Flow channel restrictors

- Custom designs

- Special voltage heaters

- Hazardous area designation

Accessories

- Heavy duty support cart

- HPU cart mount

- Adaptors

- Pressure instruments

- Heat control

- Hot oil control units

- Manual hand-held pendant with two-position momentary switch (standard)

- Automated push-button control with position indication lights (optional)

- Stand-alone Heat Control Panel (optional)