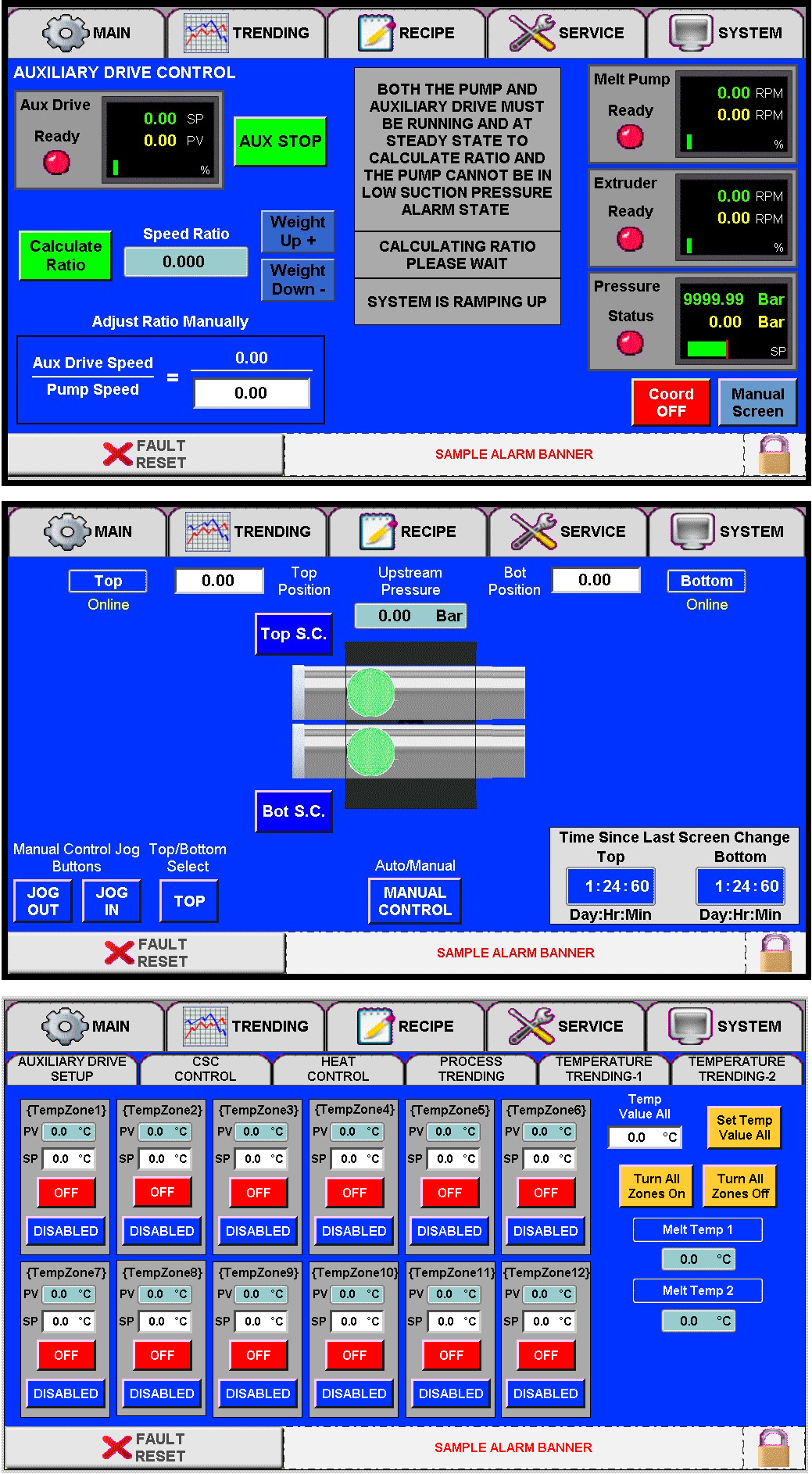

IntegraPak-500 PLC Integrated Equipment and Heat Control with Optional Line Control

Operates one (1) Gear Pump, one (1) Continuous Screen Changer – 2 or 4 Pocket and (optional) Downstream Puller/Haul-off. Includes up to twelve (12) Heat Zones.

Product Description

PLC: Allen Bradley (or B&R Automation)

HMI: 10” color touch screen

Monitors and controls inlet pressure to pump and interface with extruder drive, along with controlling piston actuation, venting locations and dwell times. Capable of integrating and coordinating downstream haul-off.

Displays

System

- Ramp

Screen Changer

- Piston positions

- Inlet / outlet / delta pressure (transducers by others if not supplied)

- Visual clean screen indication

- Time from last screen change

Gear Pump

- Pump speed, Pump current

- Suction and discharge pressure

Optional Haul-Off

- Speed

- Trim Control

- Bumpless transfer

System alarms and shut down for:

Screen Changer

- High inlet pressure

- High delta pressure

Gear Pump

- Low / High Suction

- High Discharge & Delta Pressure

- High current

Features

- Auto start (auto ramp to full production)

- Recipe storage automated product selection / start-up

- Trending

- Data logging

- Expandable I/O

- Removable flash memory data tracking and collection

- Transducer calibration

- Ethernet communication

- Ewon secure remote access module

- VNC viewer for displaying and using the control screen on a remote/larger monitor

- External communication options available upon request