Vessel Gear Pump (VGP)

Get More from Your Process

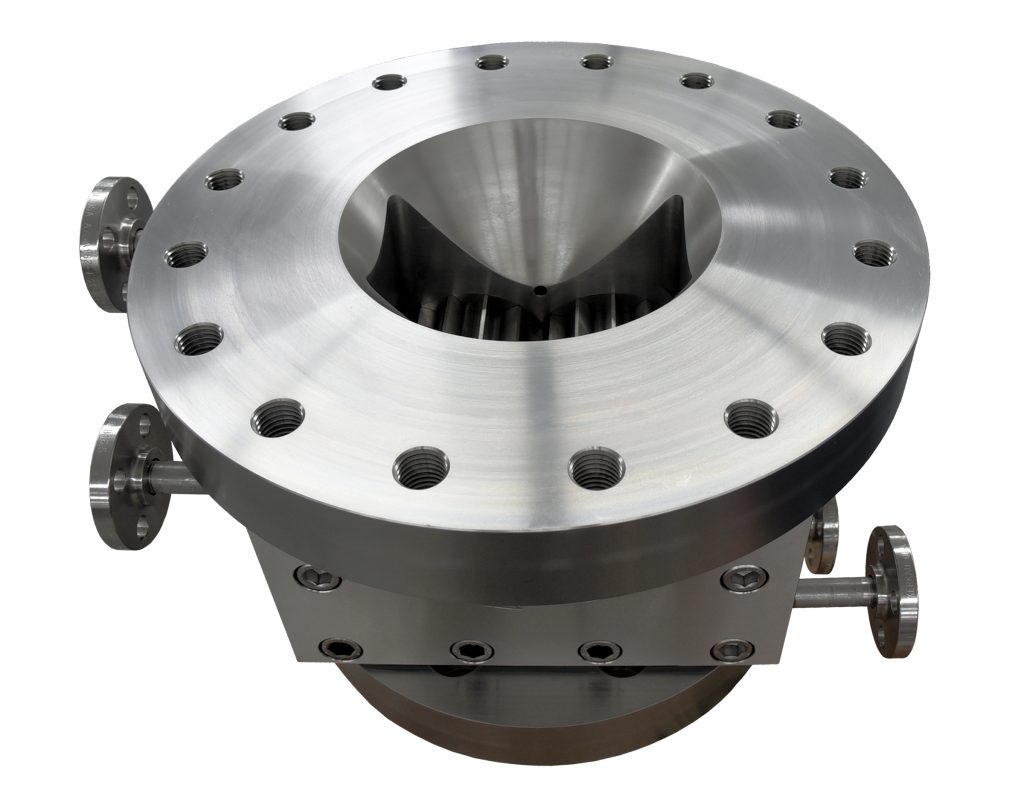

Vessel gear pumps (VGP) transfer material from reactor/devolatilization vessels, kneaders or large twin screw compounding extruders to discharge a steady volumetric output direct to the pelletizer. VGP series pump sizes accommodate pilot operations to full production.

These high efficiency pumps generate stable discharge pressures while accommodating very low-pressure infeed of high and low viscosity materials. Typical inlet pressure is under vacuum or to 145 PSI. A choice of feed openings optimize flow even under conditions of very low vessel fill levels and high vacuum. For higher viscosities and to avoid cavitation by assuring positive fill of the gear teeth, PSI offers up to 170 degrees of infeed to the gear teeth.

Specifications

| Throughput rate (pph) [kg/h] | 20 - 25,000 [11,340] |

| Displacement (cc/rev) | 7 – 6,227 |

| Temperature (°F) [°C] | Up to 600* [315] |

| Max oper. pressure (PSI) [bar] | max. 4,350 [300] |

| Differential pressure (PSI) [bar] | max. 2,500 [172] |

| Heat | Fluid |

| Vacuum (PSI) [bar] | Up to 580 [40] |

Features

- Custom vessel connection flanges – annular or square, bolted or clamped

- Designs for pre-filling under vacuum or low head pressure feed

- Small footprint and forged stainless-steel construction

- Cored housing and ANSI rated flanges for hot oil or steam heat

- Seal options include single or double mechanical seals or standard Visco seals

- Seal design accommodates fast, easy replacement, with off-the-shelf seal availability from PSI

- Through-hardened tool steel gears last up to 3X longer

- Pressure and temperature instrument ports

- Drop-in replacements for most competitors’ gear pumps

Accessories

- Support cart

- Torque limiting couplers

- Variable Frequency Drives

- Pressure Instruments

- Adaptors

- Motor encoders

- Stand-alone Heat Control Panel