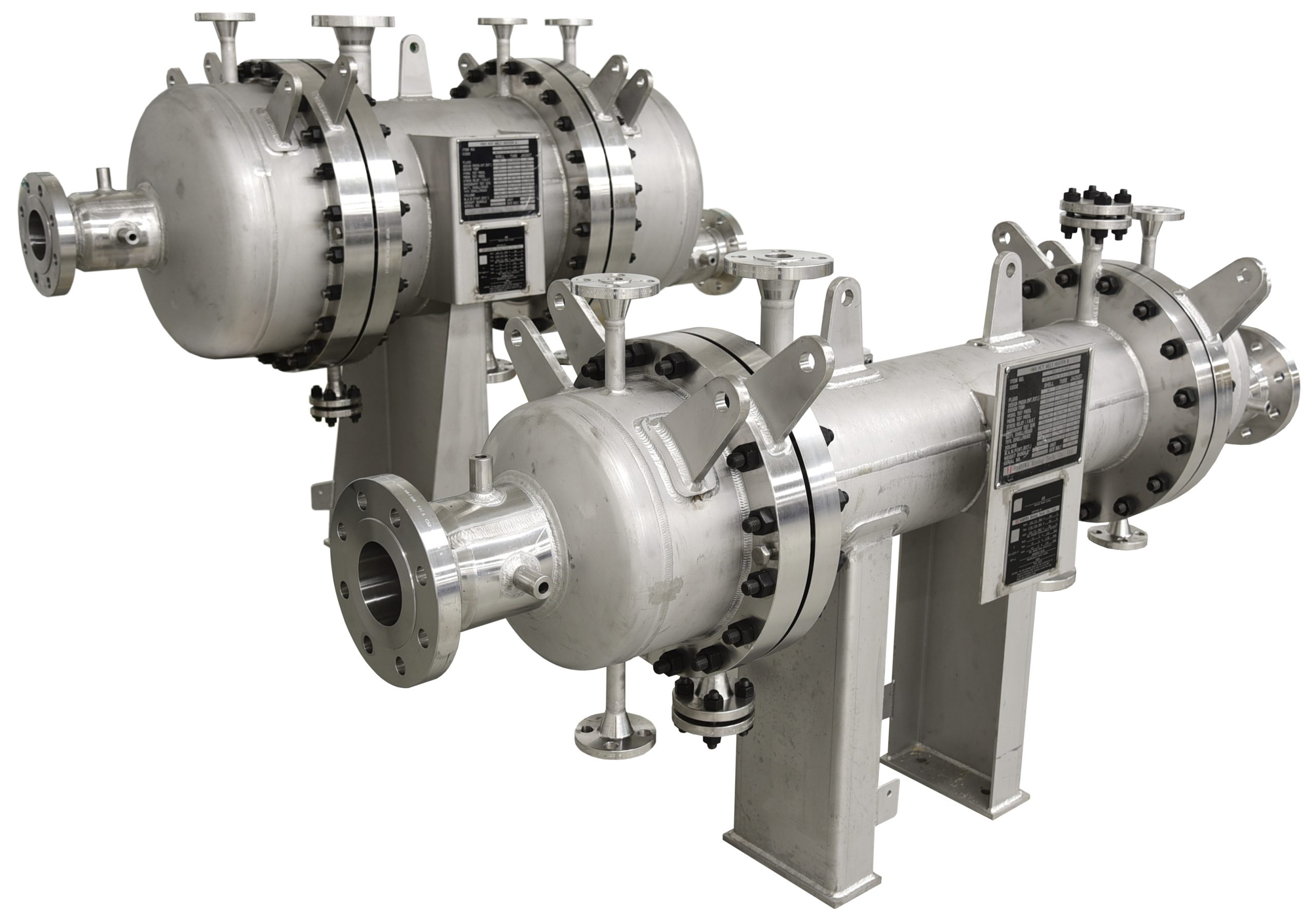

Heat Exchangers & Melt Coolers (HEX-SM)

Get More from Your Process

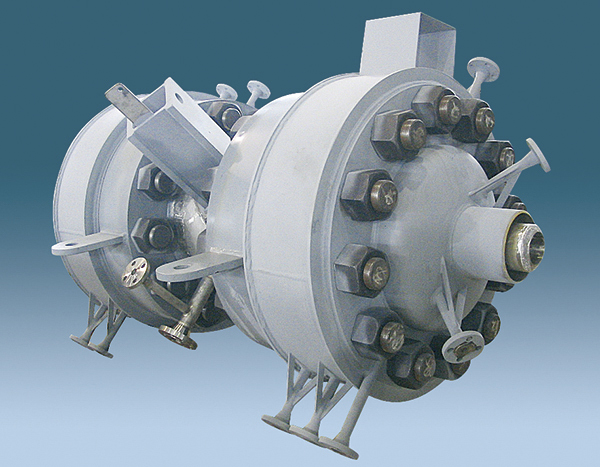

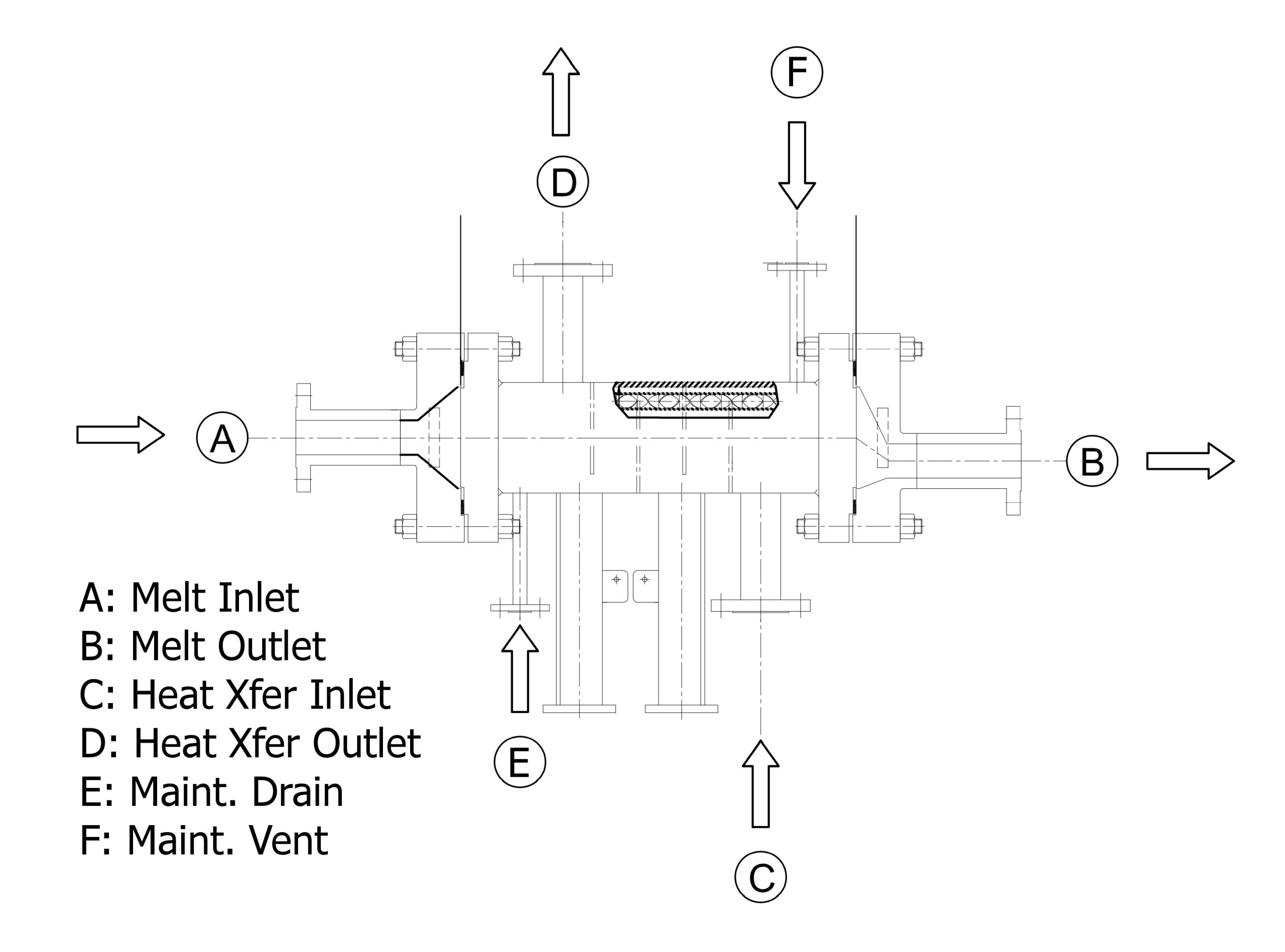

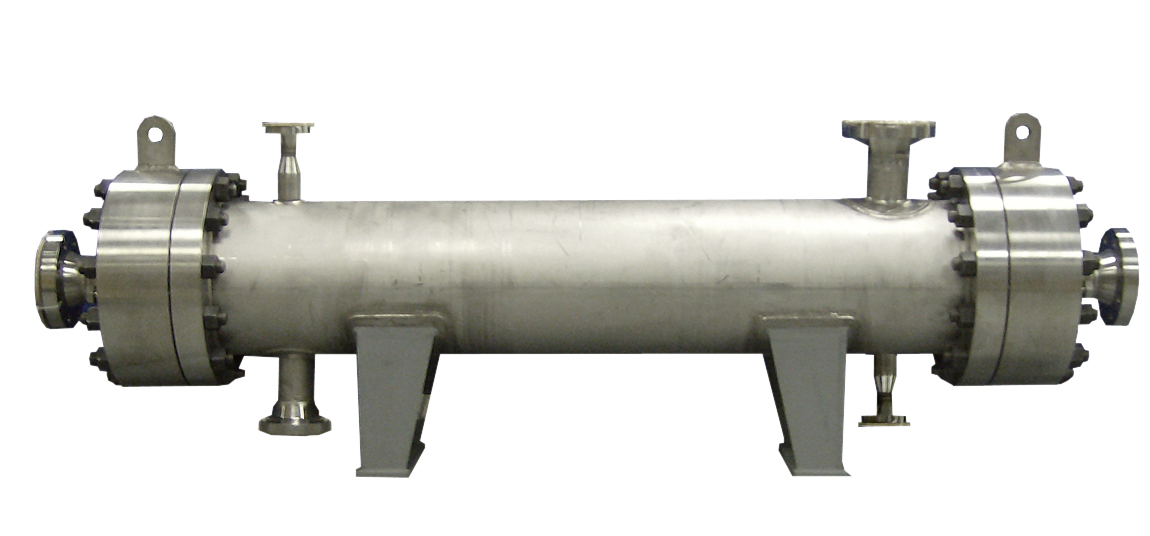

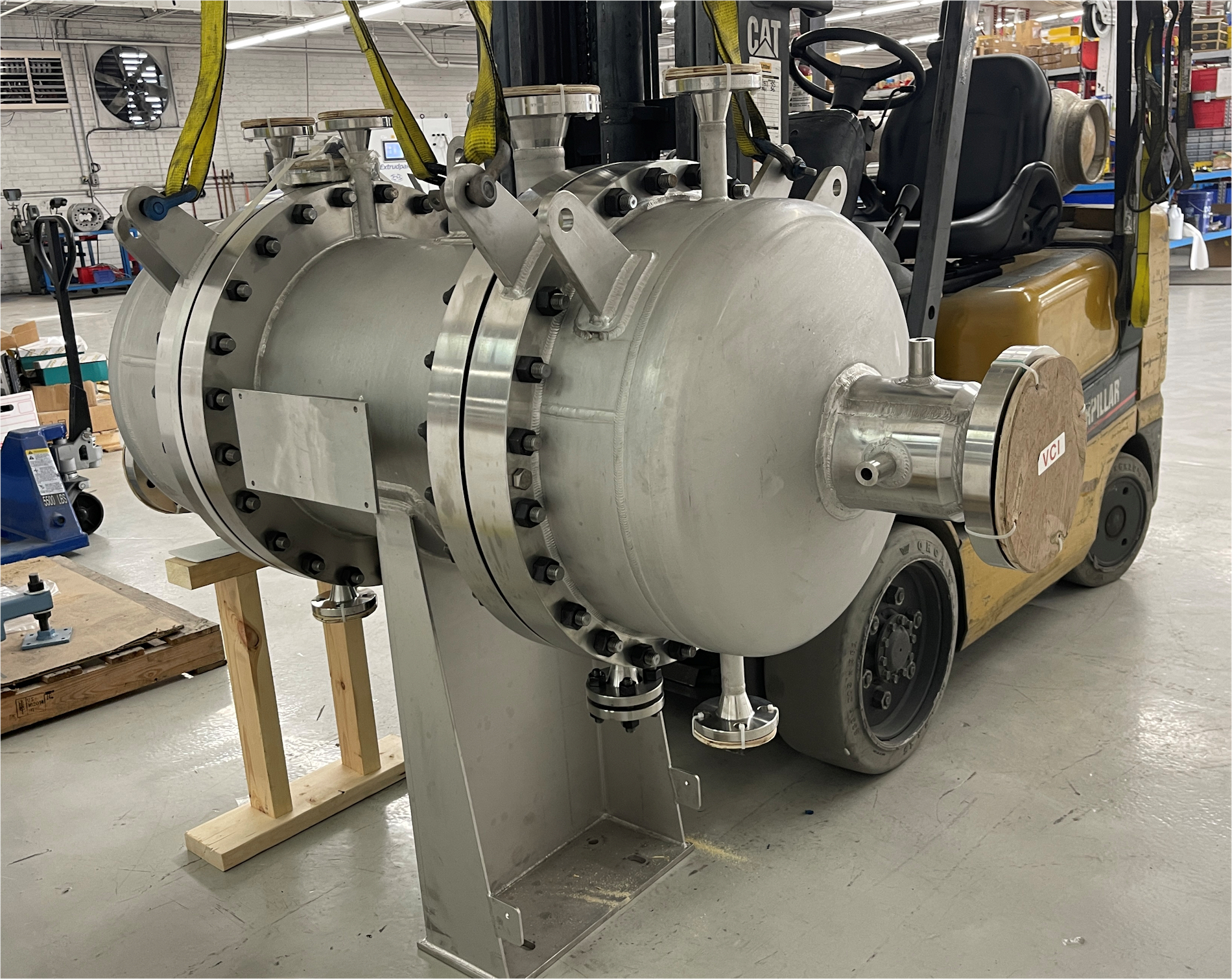

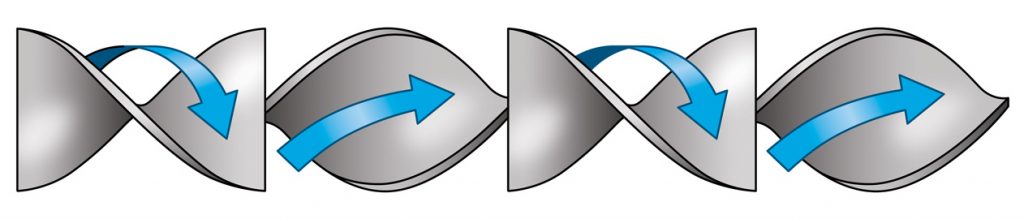

PSI Heat Exchangers (HEX-SM), also referred to as melt coolers, provide exceptional efficiency when cooling or heating viscous fluids. The countercurrent flow, single-pass shell & tube mixer design features brazed helical static mixer inserts. Brazing optimizes thermal conductivity through the tubes into the mixers or vice-versa. Removable mixer elements are optionally available for applications requiring occasional cleaning, such as product changeovers.

The static mixer inserts (alternating bow-tie twists) eliminate the insulation and fouling layer that builds up along the inner wall in conventional open-tube designs. Flow within the mixer tubes provides consistent turbulent movement that fully distributes and exposes the process fluid to the cooling or heating surface. This results in heat transfer rates three (3) to seven (7) times those of conventional open-tube heat exchangers, in turn, yielding a compact footprint and short residence times for space-critical applications. These energy-efficient heat exchangers are a smart solution for temperature control of prepolymers, polymers, and hot melt adhesives.

HEX-SM heat exchangers are custom manufactured to individual process specifications.

Applications

- Adding heat for pre-polymer reaction

- Cooling hot melt adhesive products (typically Pelletizing operations)

- Addition or removal of heat for various polymerization reactions

- Heat removal in exothermic reactive processes

- Maintaining constant hot oil temperature in recirculation loops

- Heating viscous food products

- Heating sealants

Specifications

- Heat exchanger type: Shell and Static mixer inserted tube type; straight tube, single pass

- Material: Stainless Steel (others, by application)

- Operating pressure: Tube side – 435 psi (30 bar) / Shell side – 145 psi (10 bar)

- Operating temperature: Tube side – 535 °F 280 °C / Shell side – 535 °F 280 °C

- Standard code: ASME Sec.VIII, Div.1 & TEMA Class “C”

Features

- Heat transfer coefficients 3-7x higher than conventional open tube designs

- Highly polished, streamlined flow, no dead spaces

- Uniform temperature output for each tube – no laminar flow

- Short residence time

- Compact, space-saving design

- Processes fluids with low to high viscosities

- No moving parts to maintain

Options

- Removable mixer elements

- Application-specific materials of construction (incl. for highly corrosive materials)

- Pressure: Exceeding 5,700 psi (350 bar)

- Viscosities: Exceeding 20,000 Pas (20,000,000 cp)

- Certifications: ASME, DIN, Others