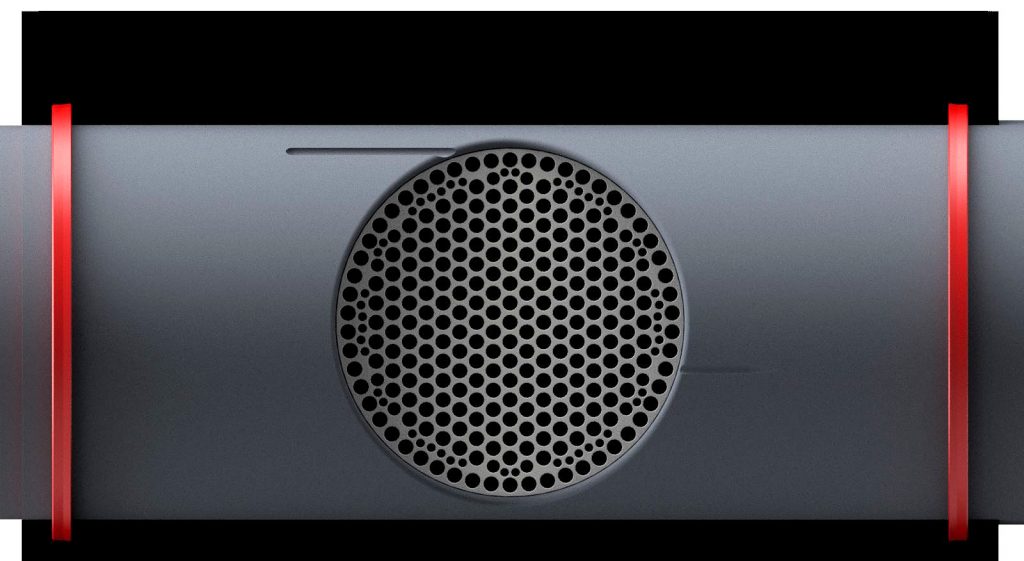

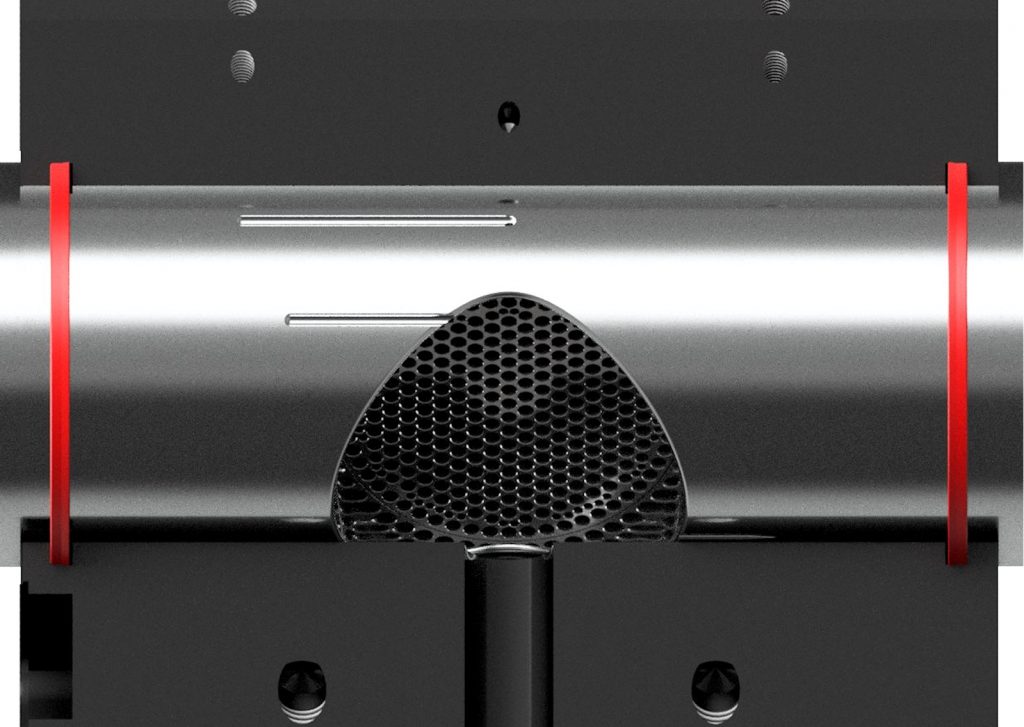

Low Viscosity (LV) Seal – Patented

Get More from Your Process

Proven with hard-to-seal, high flow materials (e.g. 2000 MFI / 16 Pa-s at 10 Sec-1), PSI’s patented low viscosity sealing system solves pesky leak issues on bolt-type screen changers. The highly effective seals are well proven in a broad range of melt blown and adhesive applications in plants around the world. Rated for applications with process temperatures up to 525°F (270°C), the long-lasting seals are easy to access and do not require removal of the screen changer from the line for maintenance.

Why needed? One of the primary advantages of a bolt-type screen changers is having no mechanical seals. The standard design features controlled-gap sealing which uses the polymer’s viscosity to simultaneously lubricate and seal. While this works quite well for most polymers, the high fluidity of ultra-low viscosity materials allows migration across the closely held bolt to housing clearances and results in varying degrees of leakage to atmosphere. PSI’s patented LV Seal solves this.