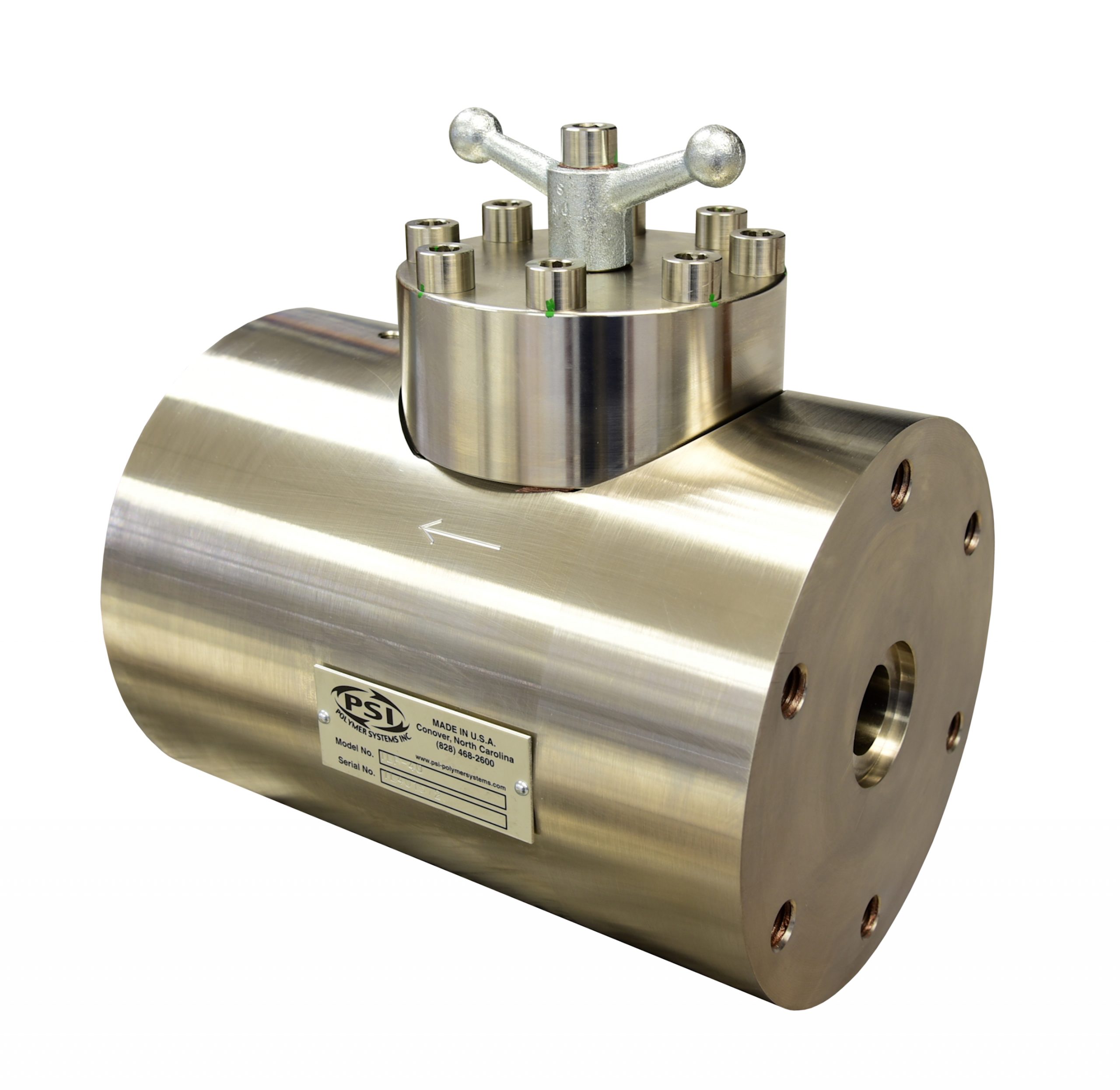

In-line Filter (ILF)

Get More from Your Process

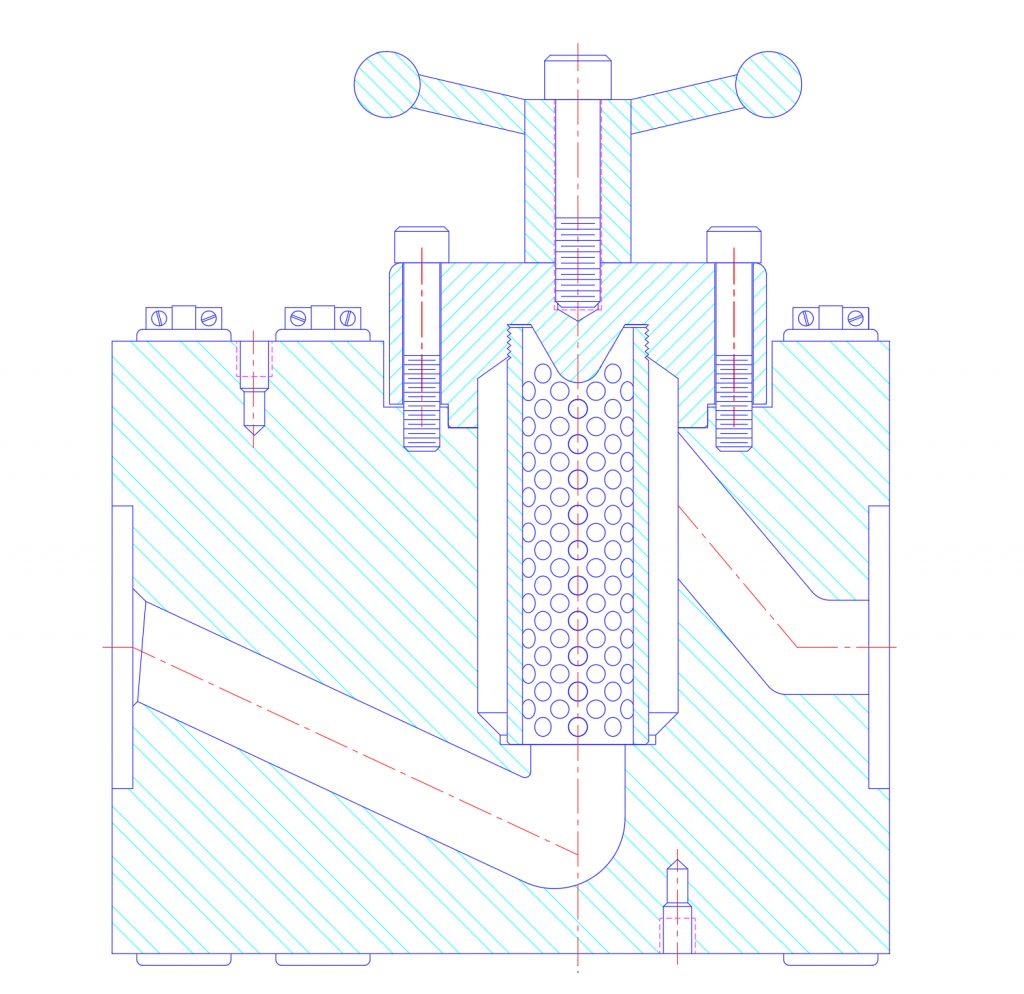

The In-Line Filter (ILF) is a convenient, low-cost side-access melt filter for batch runs. Screen changes can be accomplished in as little as five minutes and do not require line disassembly. Used in a broad range of applications including filtration for gels in film and small carbon particulate in optical grade polymers, these compact filters have no moving parts and can be applied to extruders as small as 2 inches in diameter while easily accommodating the output of a 6-inch extruder. Cylindrical filter elements, which can be wire cloth or pleat offer greater filter area for longer runtimes between screen changes or otherwise to reduce pressure drop when filtering to fine micron levels.

Specifications

| Temperature °F [°C] | Up to 650 [343] |

| Max oper. pressure PSI [bar] | max. 10,000 [670] |

| Control zones (housing) | One (1) |

| Heating | Electric/Fluid |

| Filter Area | Screen Dimensions | Heater | Weight | ||||||||

| Model | Max. Throughput* | Diameter x Length | Diameter x Length | ||||||||

| Lb/h | Kg/h | In² | cm² | inch | inch | mm | mm | kW | Lb. | Kg | |

| ILF-20 | 1,250 | 567 | 20 | 129 | 1.512 | x 4.270 | 38.405 | x 108.455 | 1.65 | 70 | 32 |

| ILF-40 | 2,500 | 1,134 | 40 | 258 | 2.262 | x 5.618 | 57.455 | x 142.697 | 3.5 | 140 | 64 |

| ILF-80 | 5,000 | 2,268 | 80 | 516 | 3.512 | x 7.375 | 89.205 | x 187.325 | 9 | 476 | 216 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||||

Features

- Long-life, compact design

- Cylindrical long-run filter elements

- Accepts wire cloth or pleat filters

- No moving parts or seals to wear out

- No line disassembly for filter change

- Tool steel construction

- Bolted, leak-tight connection

- No hang-up areas

- Low maintenance

Options

- Integral lever-operated divert valve

- Internal fluid heat/cool

- Stainless steel, H13 or Inconel construction

- Pleated filter elements for fine micron filtration

- Special heater voltage

- Chrome or nickel plating

- High temperature to 850°F [454°C]

Accessories

- Spare filter assembly

- 18V Cordless Screen Cut-off Tool

- Adapters

- Heat control

- Pressure Instruments