Screen Changer with Integral Divert

Get More from Your Process

CSC-DV

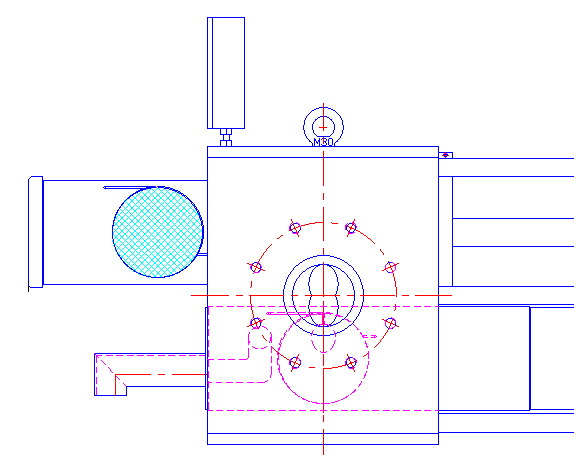

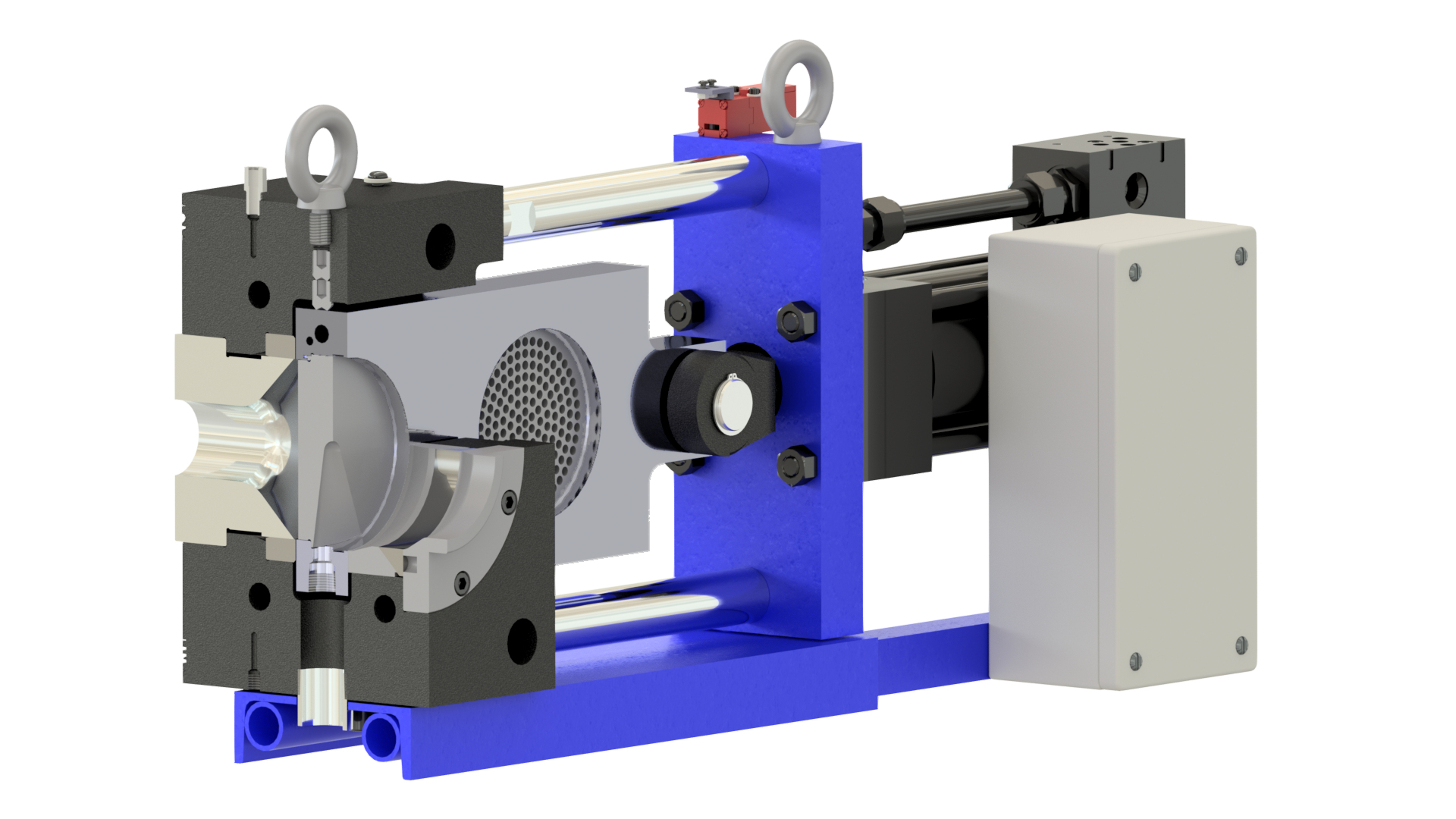

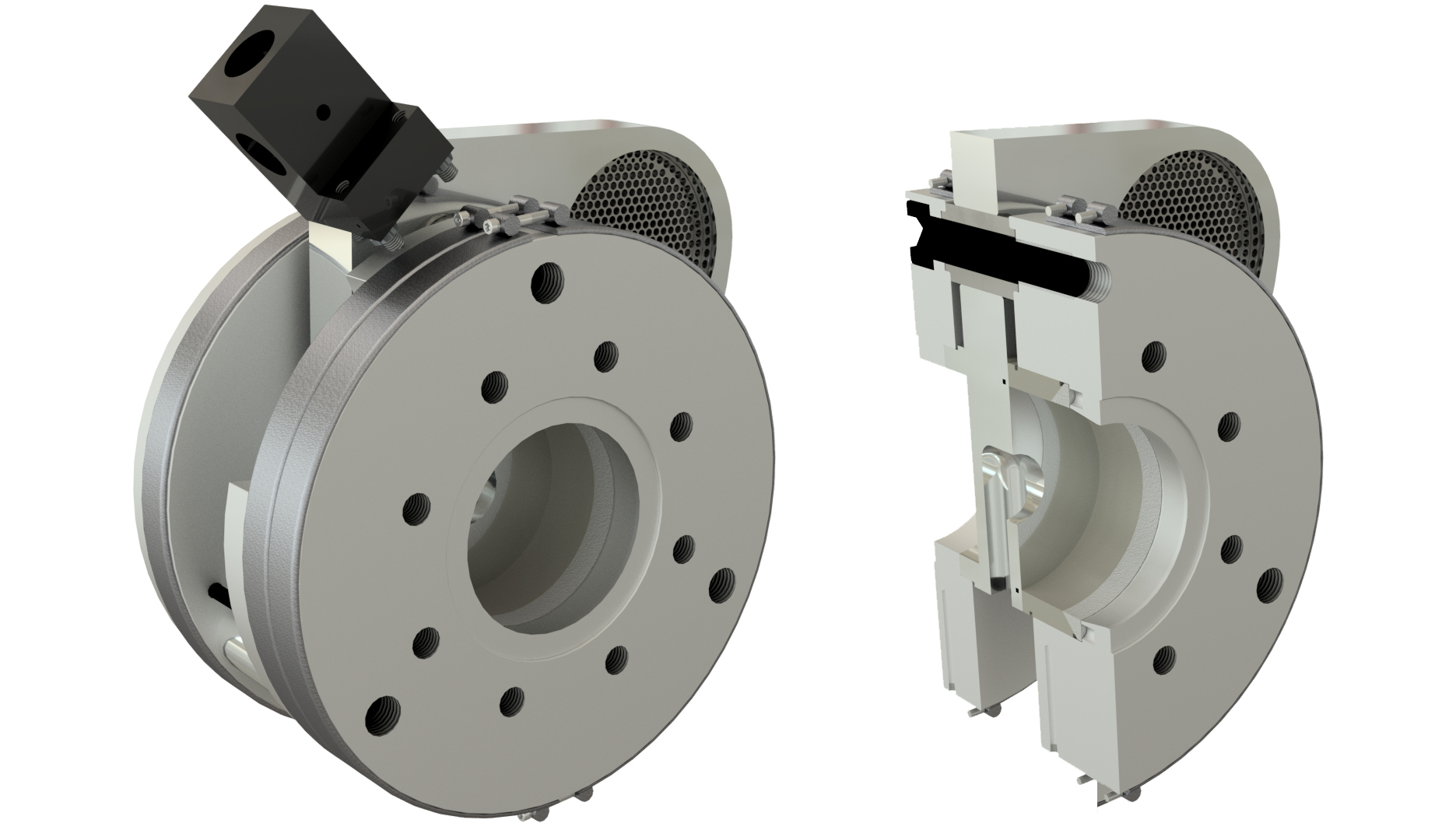

Continuous screen changer with integral divert port (CSC-DV)

Continuous flow with integral divert for applications able to tolerate a multi-second shift to divert. In the process position, the melt flow passes through upper and lower filter packs. Filter changes and air purge functions are as standard for continuous screen changer operation. Orientation is available for horizontal and vertical mounts.

To operate in divert mode, the lower cross-bolt fully retracts, withdrawing the on-line filter from the melt flow and accessing the divert port. The upper filter remains online. Because the divert ports to atmosphere, all material flows through the divert port, bypassing the upper filter.

HSC-DV

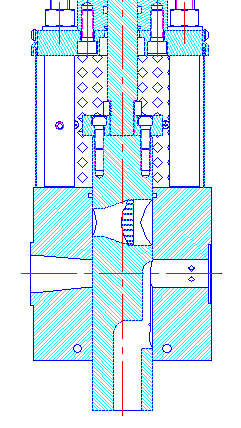

Hydraulic Slide Plate (single filter) screen changer with integral divert port (HSC-DV)

Discontinuous, single filter shifts to/from divert in approximately one (1) second or less. HSC/DV’s are a cost-effective approach for processes where die flow must be rapidly established to avoid freeze-off and where the line can be idled or stopped for screen change. Orientation is available for horizontal and vertical mounts.

DSC-DV

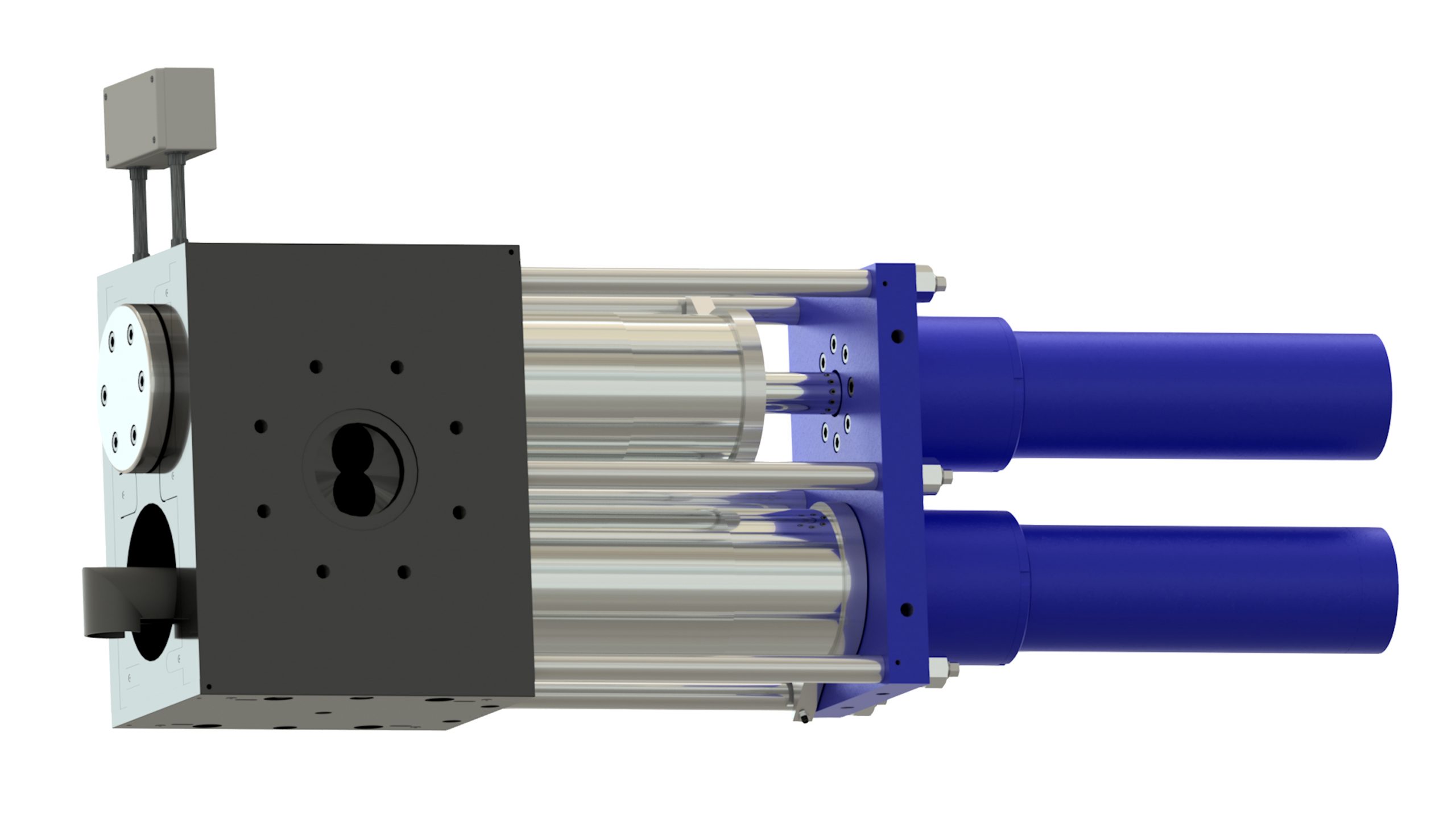

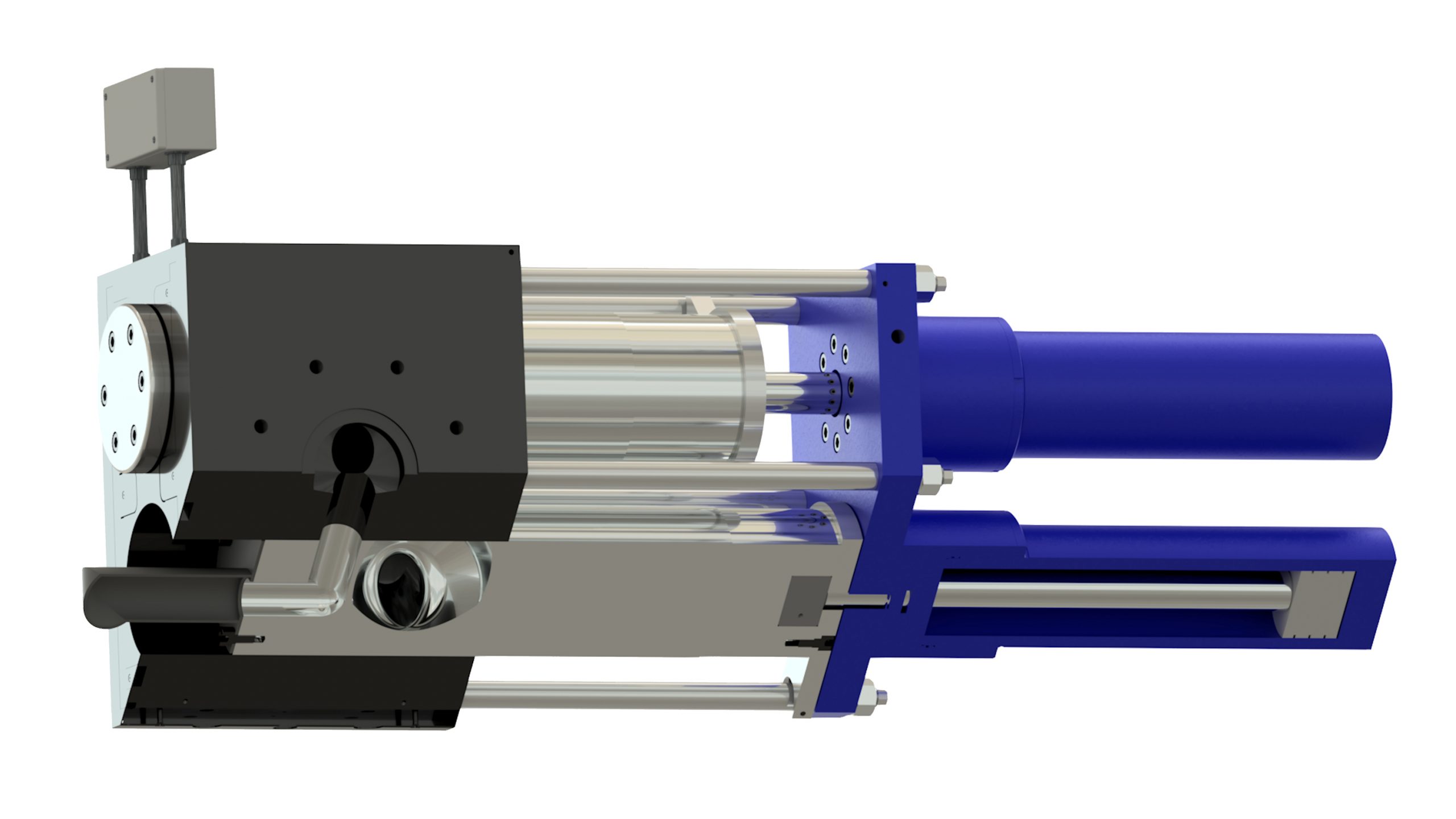

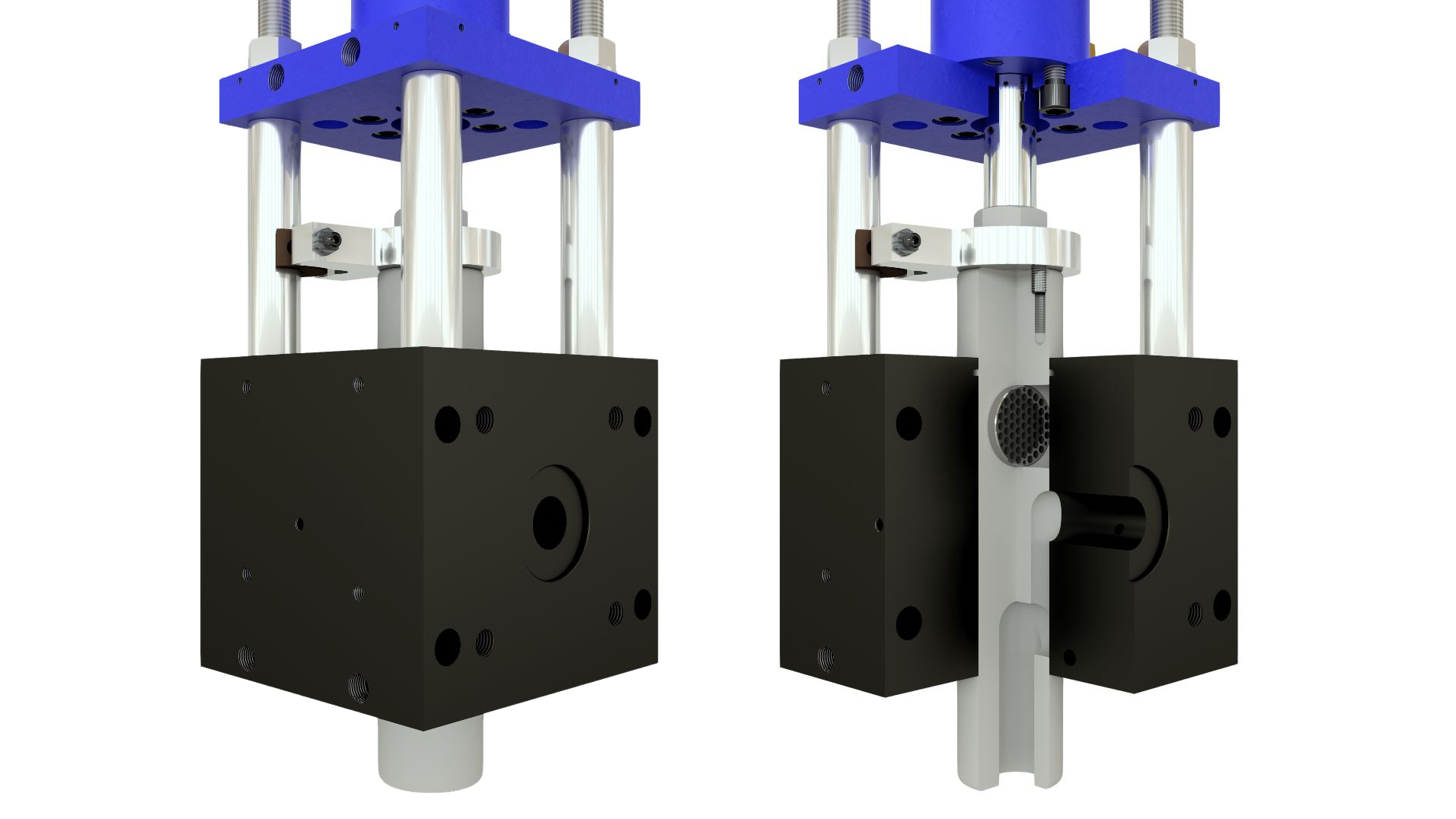

Discontinuous screen changer with integral divert port (DSC-DV)

Discontinuous, single filter shifts to/from divert in approximately one (1) second. DSC/DV models feature an extended cross-bolt design, providing the ability to contain the online screen pack within the housing while operating the line in momentary divert mode. This eliminates air introduction when the screen is reintroduced to flow. For screen change the cross-bolt fully retracts in divert position.

MSC-DV

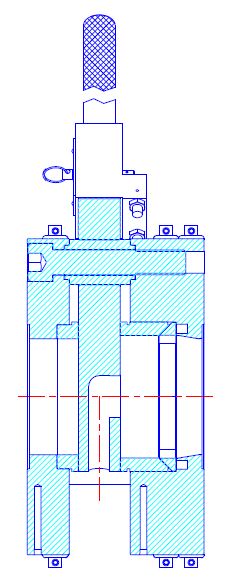

Manual screen changer with integral divert port (MSC-DV)

The MSC-DV start-up diverter is a low-cost option for compounding and other lines where melt consistency must be established and verified before introduction to the downstream process. Upon material verification, the line is momentarily stopped and a convenient throw-handle or ratchet brings the clean screen pack on line. Mechanical seal options are available for various viscosity and temperature ranges.

ILF-DV

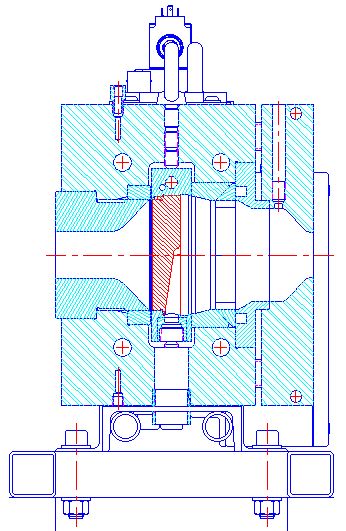

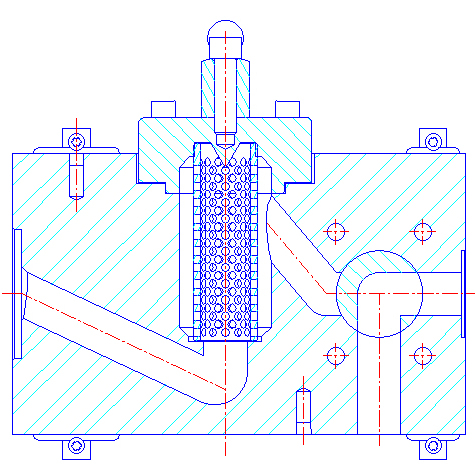

In-Line Filter (tube filter) with integral divert port (ILF-DV)

The ILF-DV start-up diverter is an attractive option to the MSC-DV for lines requiring longer run times between shutdown for screen changes, and/or require fine-micron filtration. Used for compounding and other lines where melt consistency must be established and verified before introduction to the downstream process, the ILF-DV tube filter, requires line shut down to actuate the divert valve. Valve actuation can be manual or automated. The ILF-DV has no seals to replace.