Uniflo Static Mixer (USM)

Get More from Your Process

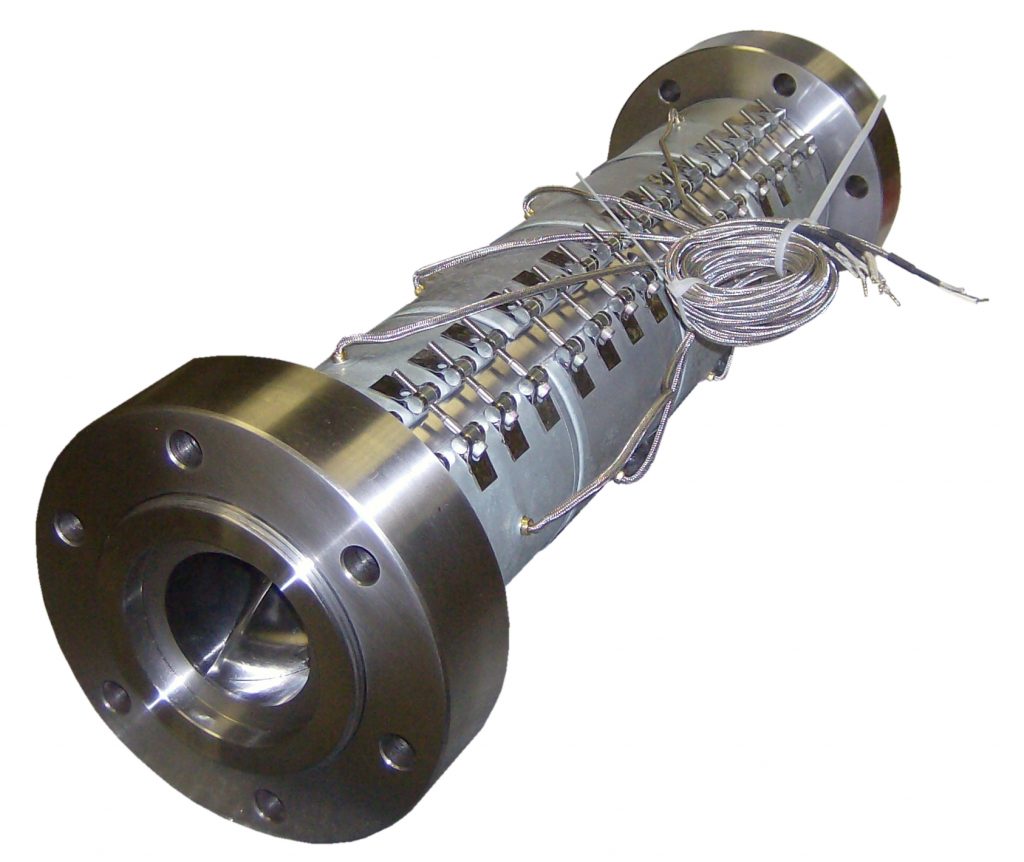

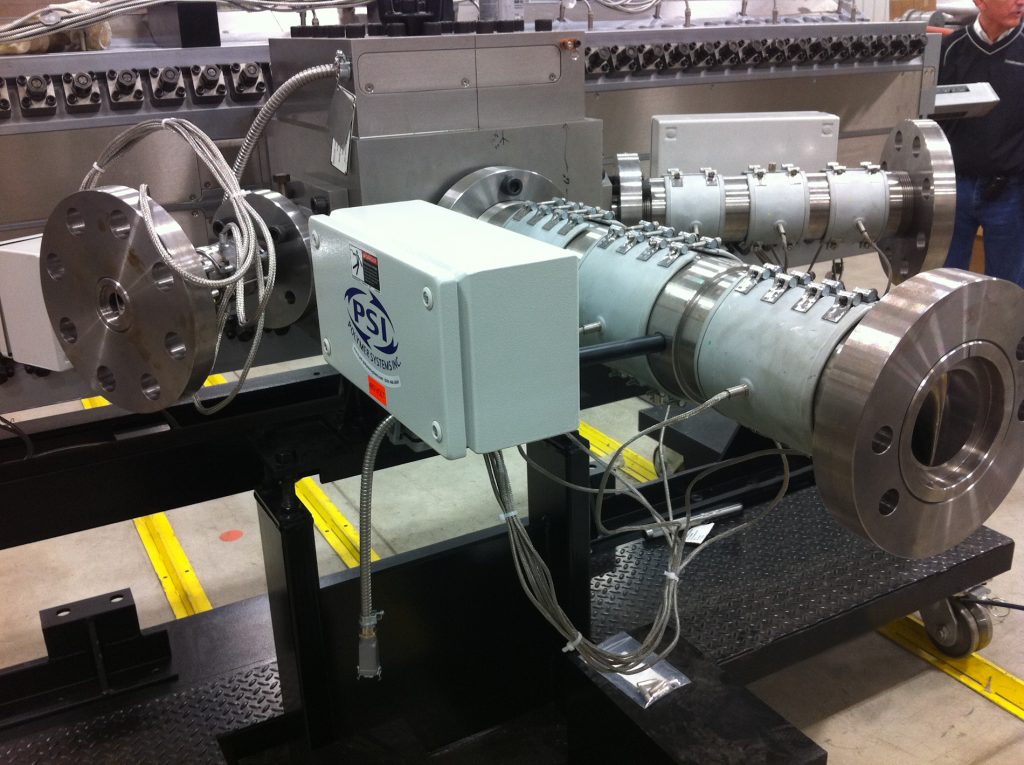

Uniflo Static Mixers (USM) provide continuous in-line mixing for polymers, colorants, adhesives, and other fluids. Highly polished, alternating 90° helical elements (alternating bow-tie twists) provide radial and axial blending over a short length to assure total mixing of compounded materials or to flatten melt temperature gradients. USM mixers are made with high-strength elements, have no moving parts, and produce an exceptionally low drag coefficient. The mixing element is easy to remove for fast material changeovers and convenient maintenance.

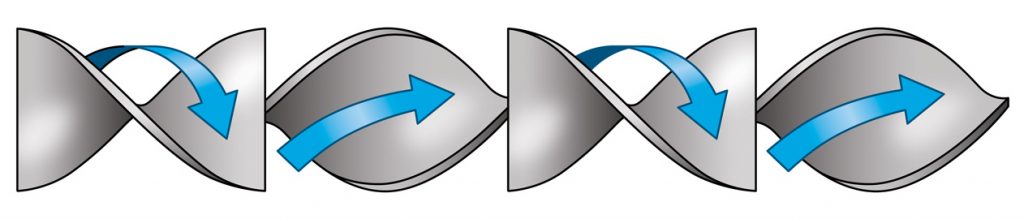

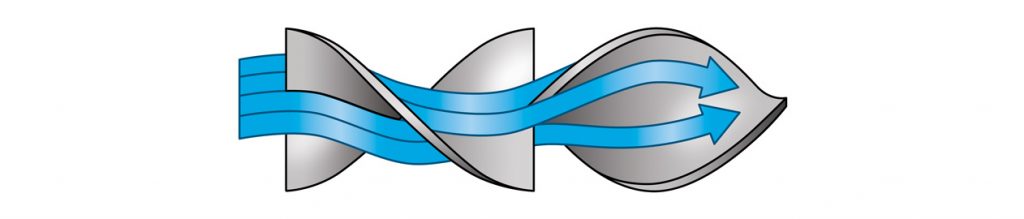

Material flow over each element in the Uniflo Static Mixer simultaneously splits, blends, and changes direction, ensuring a homogeneous output.

Each successive element splits the flow such that the number of splits squares the previous number. For example, the first element splits the flow in two. The second element splits this result into four, the next into eight.

- A 6-element mixer splits the flow 26 (64) times.

- A 9-element mixer splits the flow 29 (512) times.

Flow is non-linear. Constant directional change within the static mixer moves material at the center out to the wall and from the wall inward to the center.

Specifications

| Element diameters | .75-inch to 4-inch (19 mm -100 mm) |

| Elements per mixer | 6 or 9 |

| Heating | Electric |

| Barrel construction | Alloy Steel |

| Extruder Output | |||

| No. Elements | Diameter (inch) | Lb/hr | Kg/hr |

| 6 | 1.00 | 50-800 | 25-365 |

| 6 | 1.25 | 100-1,750 | 45-800 |

| 6 | 1.50 | 200-2,500 | 90-1,135 |

| 6 | 2.00 | 500-4,000 | 230-1,815 |

| 6 | 2.50 | 600-6,500 | 270-3,000 |

| 6 | 3.00 | 1,000-10,000 | 455-4,550 |

| 6 | 4.00 | 1,800-18,000 | 800-8,000 |

| Extruder Output | |||

| No. Elements | Diameter (inch) | Lb/hr | Kg/hr |

| 9 | 1.00 | 50-200 | 25-90 |

| 9 | 1.25 | 50-450 | 35-200 |

| 9 | 1.50 | 100-850 | 45-390 |

| 9 | 2.00 | 300-2,000 | 135-910 |

| 9 | 2.50 | 800-2,500 | 365-1,135 |

| 9 | 3.00 | 1,000-5,000 | 455-2,270 |

| 9 | 4.00 | 1,800-9,000 | 800-4,000 |

Features

- Excellent mixing or blending

- Eliminates in-process thermal gradients

- Highly polished high-flow stainless-steel mixing elements

- Removable mixing element for quick material change

- Short residence time

- No dead spaces for product to hang up or degrade

- No moving parts

- Easily adapted to most melt pipes with customizable inlet and outlet flanges

- Removes memory from extrusion process for high viscosity materials

Options

- Stainless-steel barrel and flanges

- Chrome or nickel plating

- External jacketing for fluid heat/cool

- High temperature up to 850°F [454°C]

- Housing-mounted junction box

Accessories

- Adaptors

- Heat control

- Pressure instruments