Manual Screen Changer (MSC)

Get More from Your Process

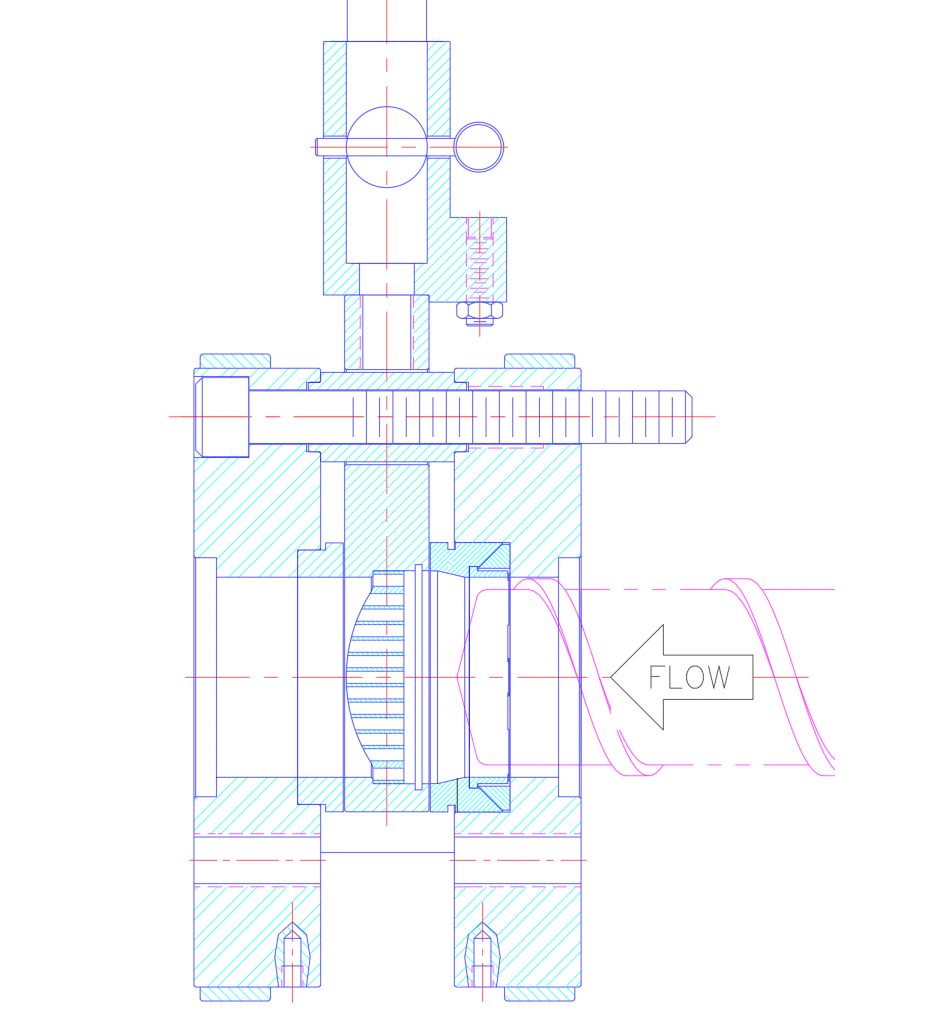

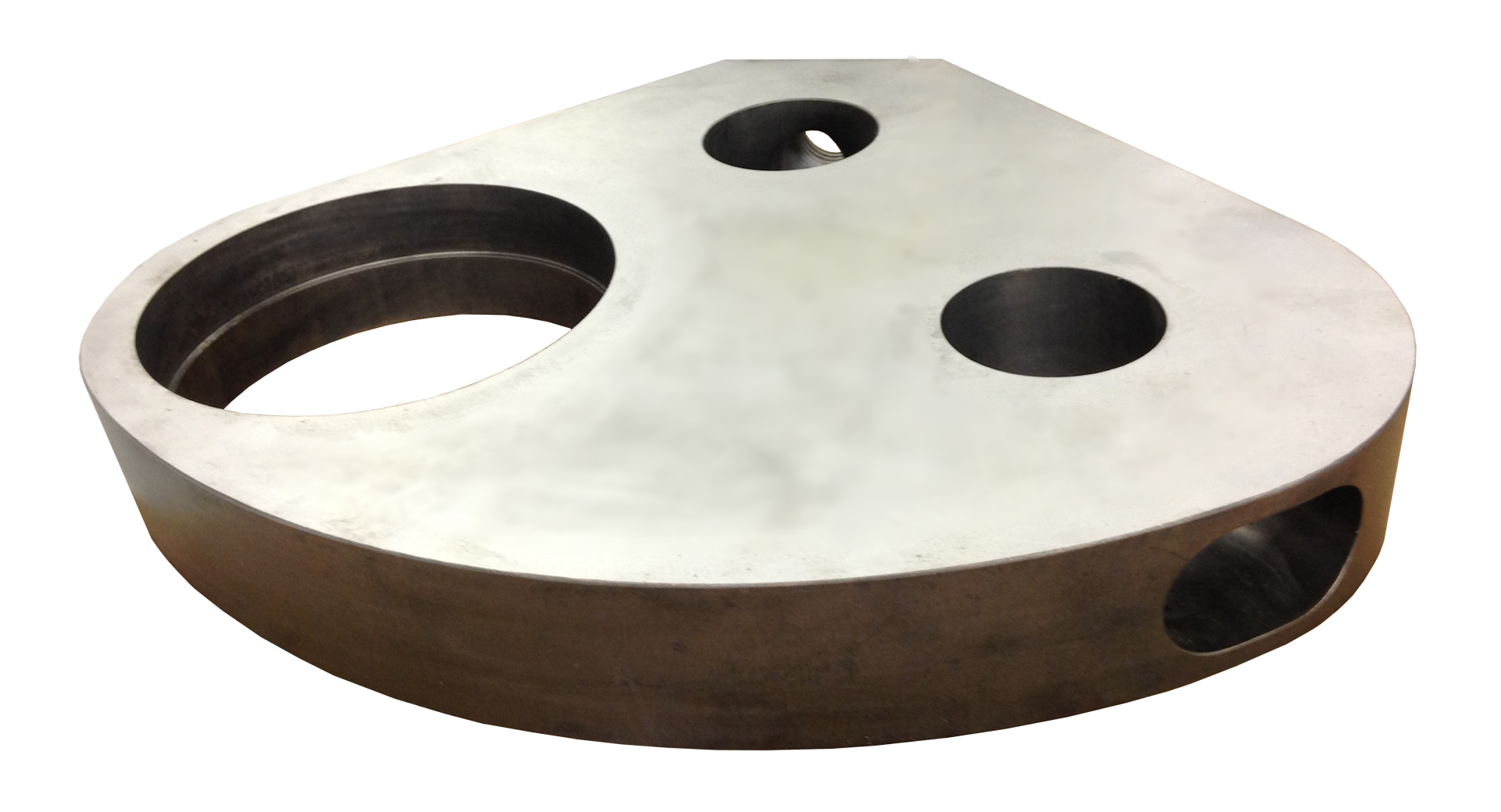

Manual Screen Changers (MSC) are an ideal solution for minimizing labor and downtime for screen changes during routine line shutdown. The compact design eliminates the need for line disassembly and uses a hand lever or optional ratchet to manually index the slide plate for screen change. The heart of the Manual Screen Changer is a pressure-activated sealing system. During screen change when the line is at rest, the slide plate coasts between the relaxed seals. Once the new screen is indexed online and the line is restarted, the seal system activates to press the seals tightly against the slide plate for reliable leak-free performance. Manual screen changer model sizes accommodate rates to 2,450+ lbs/hr (930+ Kg/h) and can accommodate extruder screw pull-through for feed screws up to 5.5″ (139 mm) diameter.

PSI Manual Screen Changers can be custom designed for specific applications and processes including higher pressures, integrated divert, and special materials.

Specifications

| Temperature °F [°C] | Up to 650 [343] |

| Max oper. pressure PSI [bar] | max. 10,000 [670] |

| Control zones (housing) | One (1) |

| Heating | Electric/Fluid |

| Max. Throughput* | Max. Clearance Bore Diam. | Screen Diameter | Screen Area | Body Heater | Weight | ||||||

| Model | lb/h | kg/h | inch | mm | inch | mm | in2 | cm2 | kW | lb | kg |

| MSC-046 | 250 | 114 | 1.58 | 40.14 | 1.83 | 46.3 | 2.7 | 16.9 | 1.1 | 40 | 19 |

| MSC-058 | 380 | 173 | 2.03 | 51.57 | 2.30 | 58.3 | 4.2 | 26.7 | 1.0 | 60 | 28 |

| MSC-076 | 650 | 295 | 2.68 | 68.08 | 3.01 | 76.3 | 7.2 | 45.8 | 1.5 | 85 | 39 |

| MSC-096 | 1,050 | 477 | 3.55 | 90.17 | 3.80 | 96.3 | 11.4 | 72.9 | 2.6 | 150 | 69 |

| MSC-116 | 1,500 | 681 | 4.21 | 106.94 | 4.58 | 116.3 | 16.5 | 106.3 | 4.0 | 210 | 96 |

| MSC-125 | 1,750 | 794 | 4.80 | 121.92 | 4.94 | 125.3 | 19.2 | 123.4 | 4.0 | 225 | 103 |

| MSC-148 | 2,450 | 1112 | 5.49 | 139.45 | 5.84 | 148.3 | 26.8 | 172.8 | 4.8 | 322 | 147 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||||

Features

- Pressure activated sealing system

- 3-position, removable swing handle

- Compact design

- Extruder screw pull-through

- Bolt-on or bolt-through extruder connection

- Low restriction breaker plate (standard pressure rating: 1500 dP)

Options

- Ratchet gear-drive slide plate shift (approx. 1/4 of the force needed for the standard handlebar design)

- High temperature, patented all-steel pressure seal

- Integral adaptors

- Integral material divert position

- Application-specific materials of construction

- 2 piece seal for color changes

- High-strength breaker plates rated for 3000 dP: recommended for high viscosity materials

- Larger breaker plate holes to reduce pressure drop

- Super plates for improved screen utilization

- Special heater voltage

Accessories

- Adaptors

- Heat control

- Support cart

- Pressure Instruments