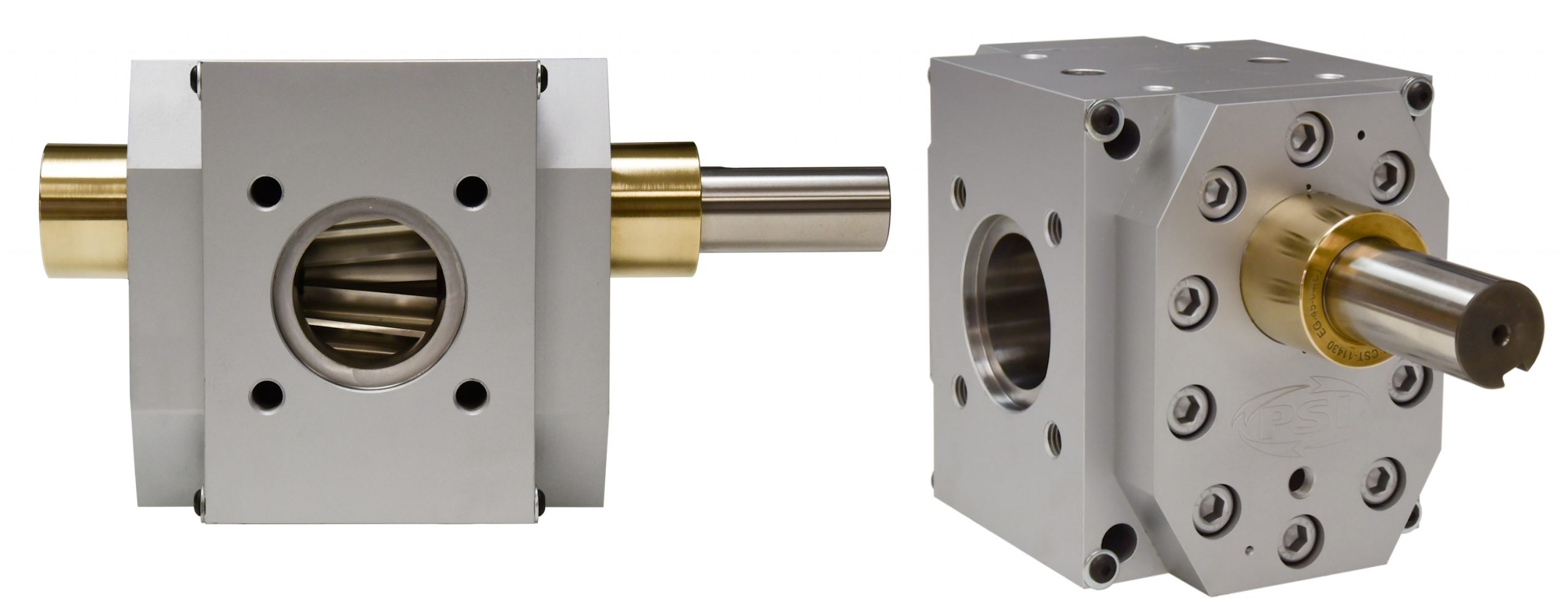

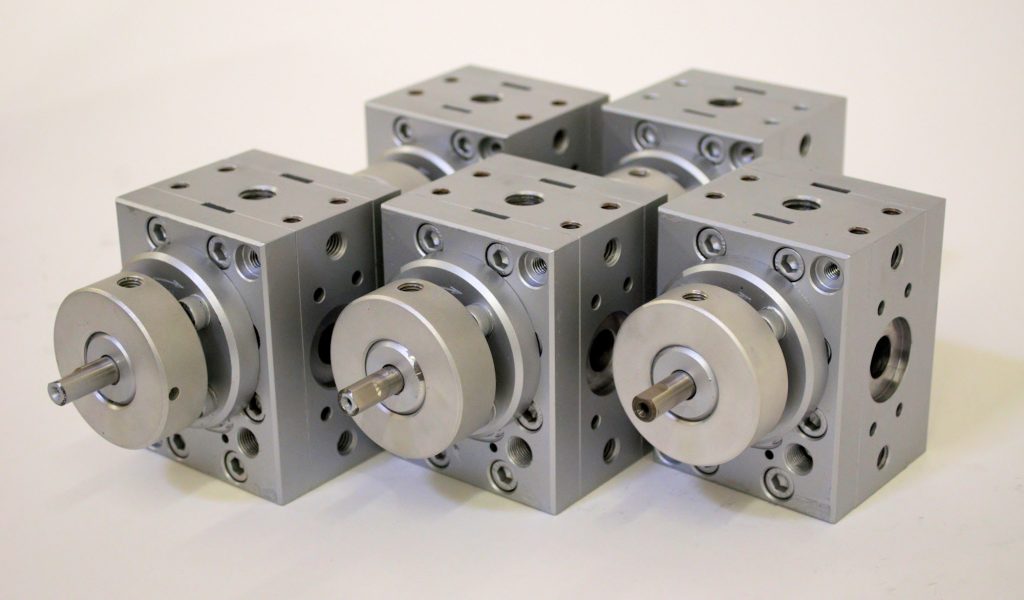

Extrusion Gear Pump (EGP)

Get More from Your Process

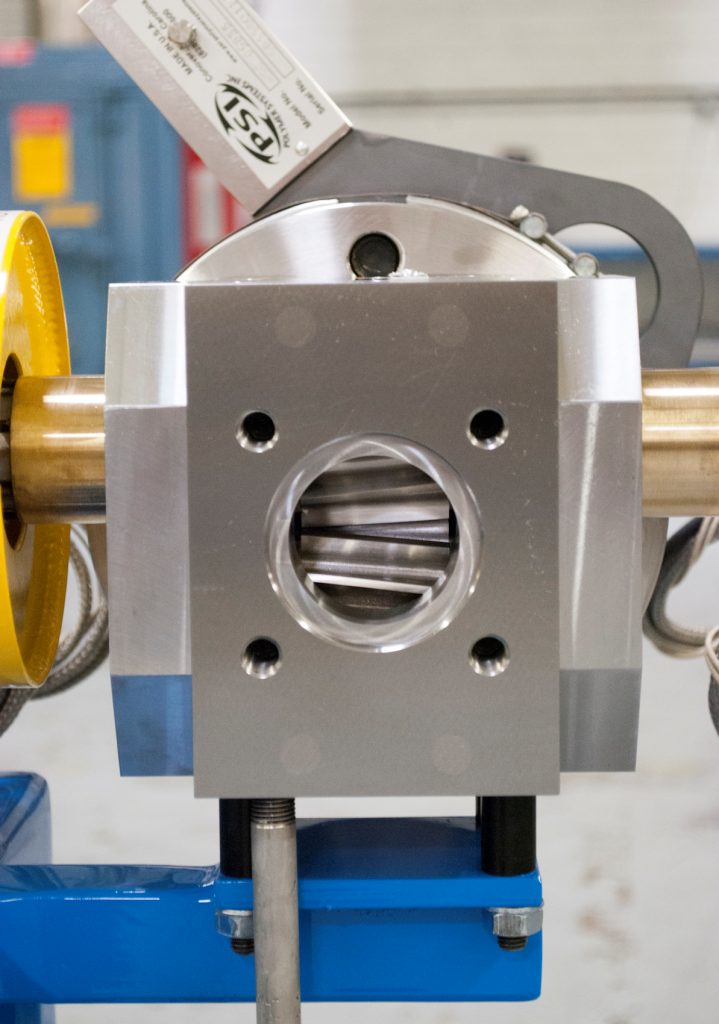

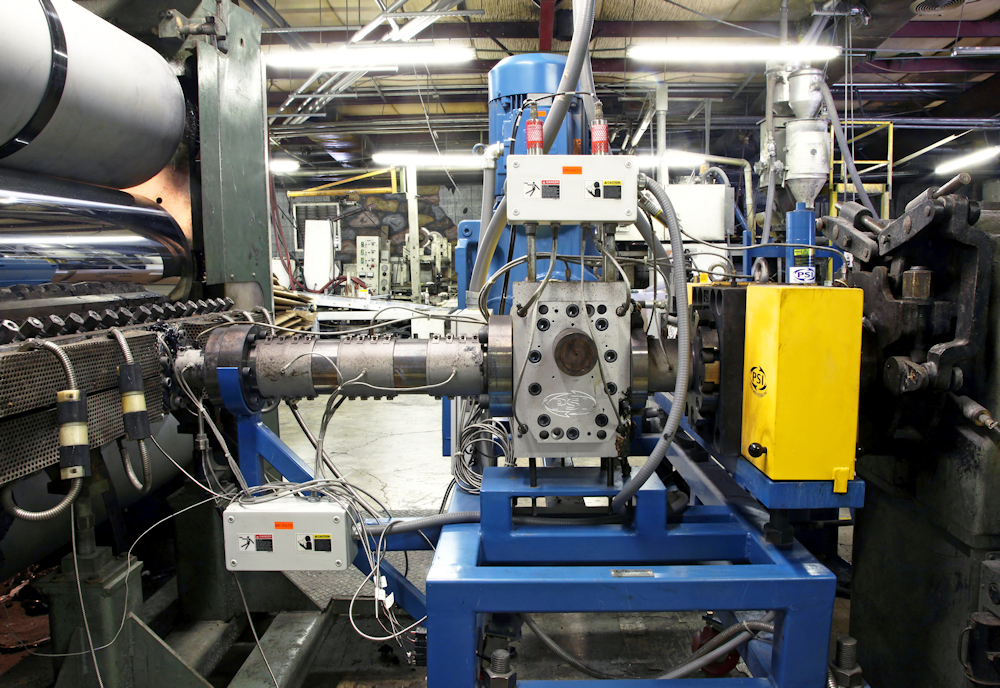

PSI Extrusion Gear Pumps (EGP) deliver exceptional metering control for polymer and hot melt adhesive extrusion and vessel applications. With pumping efficiencies typically 99.5% or better, EGP gear pumps deliver precise volumetric output and take on the pressure building function for the die. Extruder-related die pressure swings are dampened by 20:1 up to 50:1 and gauge is controlled to nominally +/- .25%. The resulting gains in product consistency and quality assure greater yield, higher profitability, and lower scrap rates.

Each full revolution of the tight-tolerance, counter-rotating gears delivers a precise linear volume of output, assuring optimal metering efficiency across the speed range. In addition to boosting extruder output per screw RPM by at least 10%, the gear pump delivers added benefits of lower shear stress, lower extruder energy consumption, lower mean processing temperature due to lower head pressures, and less wear on the extruder screw and barrel from backpressure. The PSI Extrusion Gear Pump is capable of processing highly filled polymers, fractional melts, recycled plastics, low viscosity materials and can operate at pressures up to 5,000 psi [345 bar] (4,000 psi [275 bar] ΔP).

Specifications

| Throughput rate (pph) [kg/h] | 0.06 - 41,100 [.027-18,600] |

| Displacement (cc/rev) | .11 - 6,227 |

| Temperature (°F) [°C] | Up to 650* [343] |

| Max oper. pressure (PSI) [bar] | max. 5,000 [345] |

| Differential pressure (PSI) [bar] | max. 3,500 [241] |

| Heating | Electric/Fluid |

| * Higher temperatures available. Consult factory | |

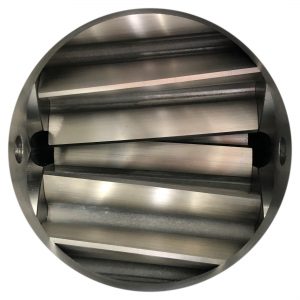

Features

- Long-life through-hardened tool steel gears

- Bronze anti-galling Visco seals

- 30%-50% more seal area than any other competitor

- Up to 99+% efficient

- Pressure and temperature instrument ports*

- Compact, low-profile design

- Drop-in replacements for most competitors’ gear pumps

*EGP-12 & 28 Series do not offer integral pressure instrument ports

Options

- Application-specific materials of construction

- Application-specific clearances

- Low viscosity, adjustment-free seals (patent pending)

- Seal cooling

- High temperature to 750°F [454°C]

- High wear-resistant materials

- Internal fluid heat/cool

- Flush/bleed ports

- Pump or cart-mounted J-box

- Servo drives for rapid response to speed changes

- Hazardous location classification

- Synchronized haul-off control (integrated into PSI supplied PLC gear pump controller)

Accessories

- Support cart

- Torque limiting couplers

- Variable Frequency Drives

- Pressure Instruments

- Adaptors

- Motor encoders

- ExtrudePak PLC: Control for one gear pump (optional downstream haul-off control available with full PLC)

- IntegraPak PLC: Integrated control for screen changer, pump, downstream haul-off and heat zones

- Stand-alone Heat Control Panel