High Pressure Gear Pump (HGP)

Get More from Your Process

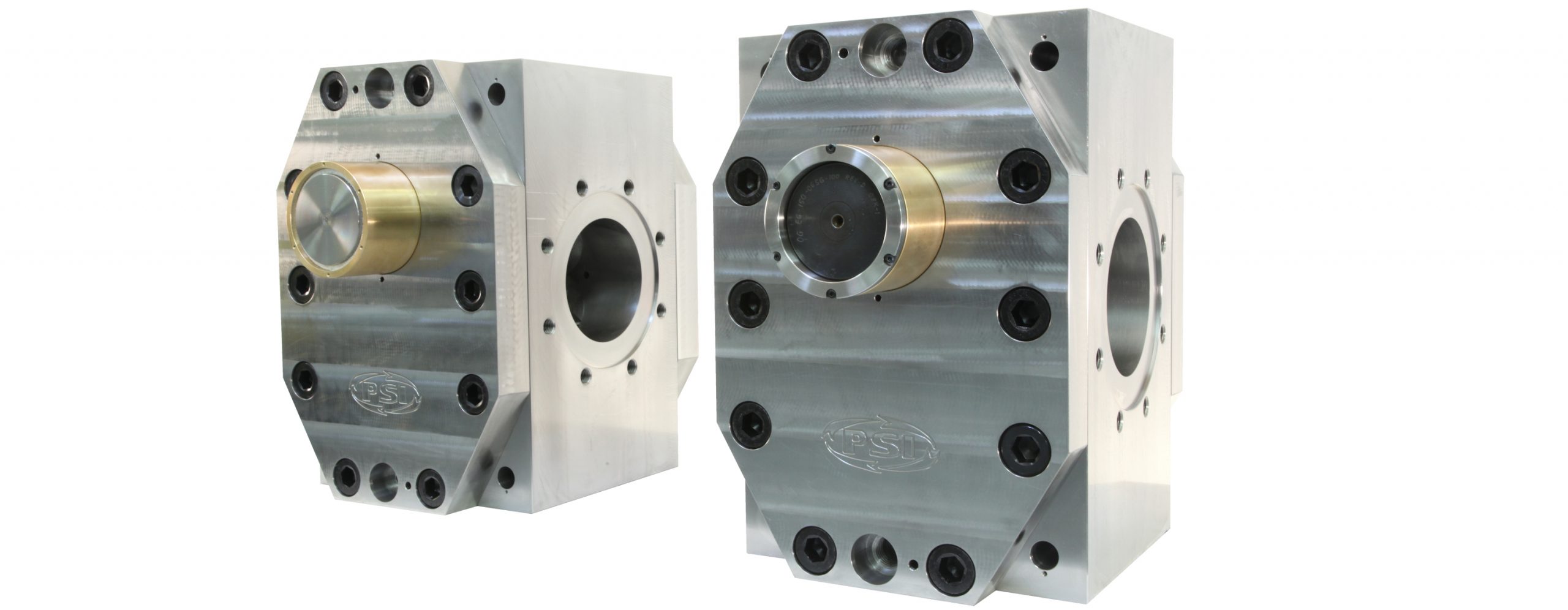

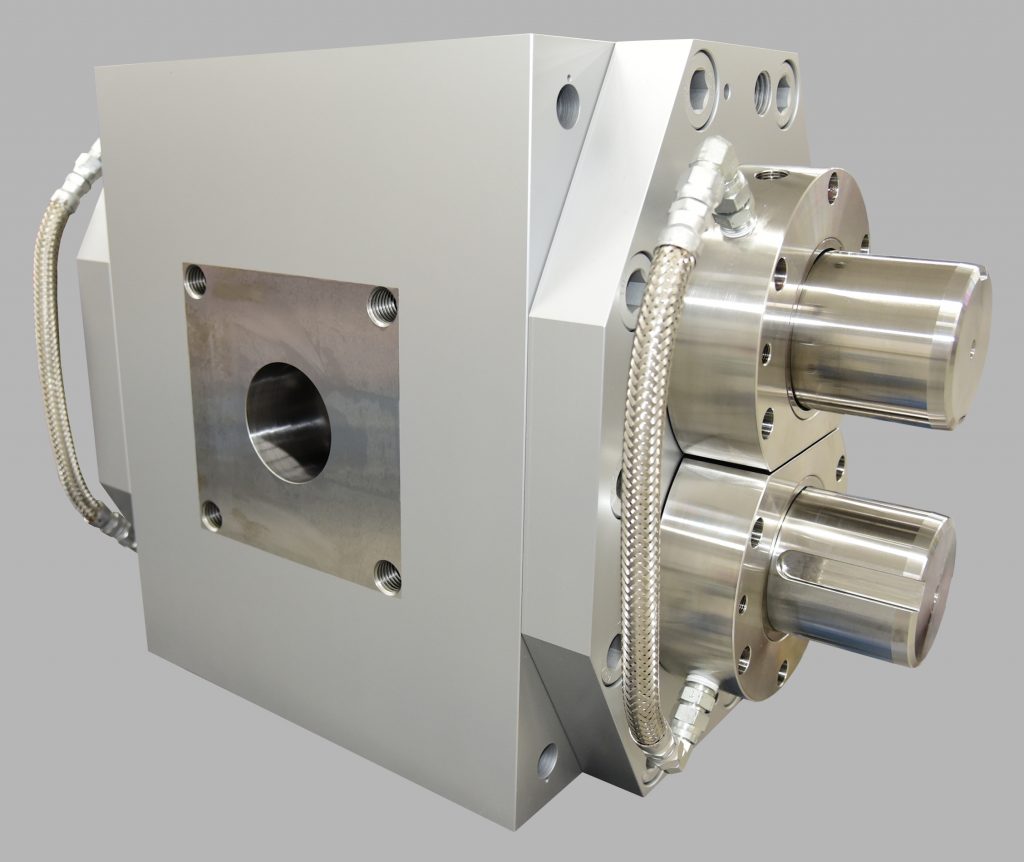

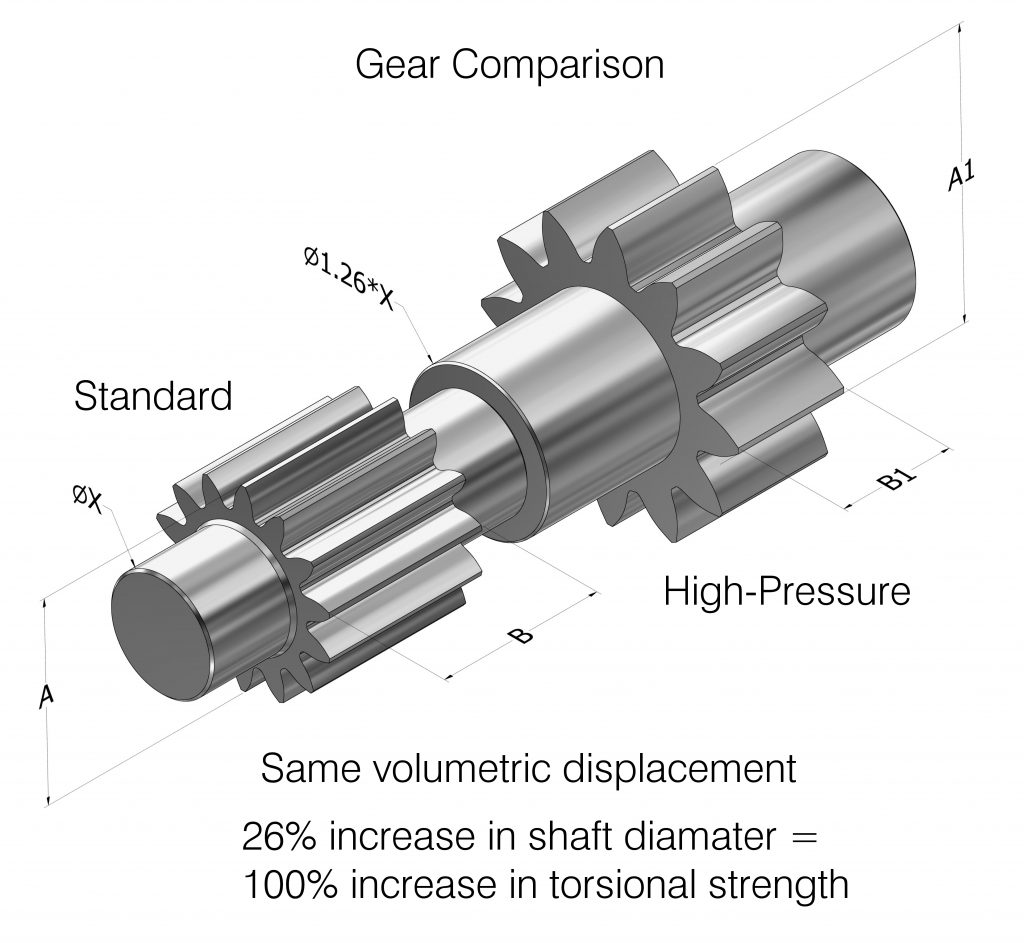

PSI High Pressure Gear Pumps (HGP) feature a long-life, heavy-duty gear design that takes on the tough demands of high-torque polymer extrusion applications. Whether working with restrictive dies or high viscosity plastic materials, the HGP delivers consistent performance where standard gear pump designs wear out or fail. These highly efficient positive displacement pumps take on the pressure building function to deliver a precise linear volume of output. This effectively takes the load off the extruder, reducing extruder amp draw and extending component life while delivering steady die pressure and uniform product gauge. The art is in the profile. PSI High Pressure Gear pumps offer large diameter gear shafts and an optimized gear tooth profile to support the high torsional strength required when processing highly viscous or fractional melt-flow polymers.

Specifications

| Throughput rate (pph) [kg/h] | 2.7 - 9,750 [1.2 - 4,423] |

| Displacement (cc/rev) | 4.03 - 1,477 |

| Temperature (°F) [°C] | Up to 650 [343] |

| Max oper. pressure (PSI) [bar] | max. 10,000 [690] |

| Differential pressure (PSI) [bar] | max. 7,500 [517] * |

| Heating | Electric/Fluid |

| * Material dependent - consult factory |

- Long-life through-hardened tool steel gears

- Non-square gear profile handles higher torque applications

- Bronze anti-galling Visco seals

- 30%-50% more seal area than any other competitor

- Up to 99.8+% efficient

- Lower bearing loads

- Pressure and temperature instrument ports

- Compact, low-profile design

- Drop-in replacements for most competitors’ gear pumps

Options

- Application specific materials of construction

- Application specific clearances

- Seal cooling

- High temperature to 750°F [454°C]

- Wear resistant materials

- Dual drive

- Internal fluid heat/cool

- Flush/bleed ports

- Pump or cart mounted J-box

- Synchronized haul-off control (integrated in PSI supplied PLC gear pump controller)

- Support cart

- Torque limiting couplers

- Variable Frequency Drives

- Pressure Instruments

- Adaptors

- Motor encoders

- ExtrudPak-100 PLC/HMI – Gear Pump Only

- IntegraPak-100 PLC/HMI Integrated Control – Screen Changer / Gear Pump

- IntegraPak-300 PLC Integrated Control – Screen Changer / Gear Pump / Haul-Off

- IntegraPak-500 PLC Integrated Control – Screen Changer / Gear Pump / Heat Control / optional Haul-Off

- Stand-alone Heat Control Panel