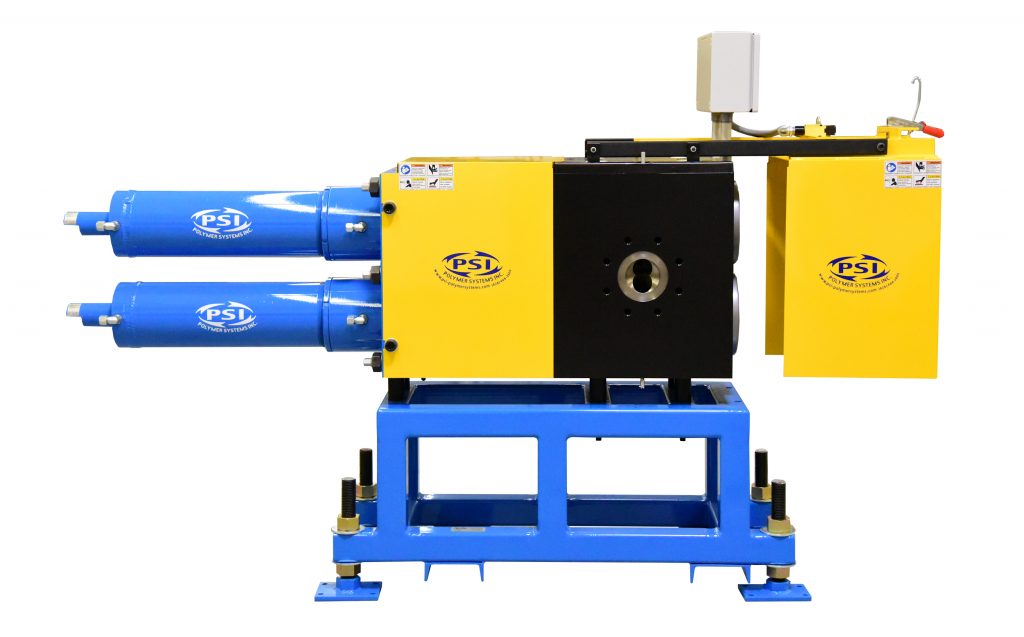

Continuous Screen Changer (CSC)

Get More from Your Process

Two (2) pocket models

Continuous Screen Changers (CSC) provide uninterrupted filtration of thermoplastic materials. No downtime or related scrap for screen changes, high reliability, lower average head pressures and higher daily output make this screen changer a perfect choice for continuous melt filtration. The low maintenance design has no mechanical seals and will operate leak-free for decades with proper care.

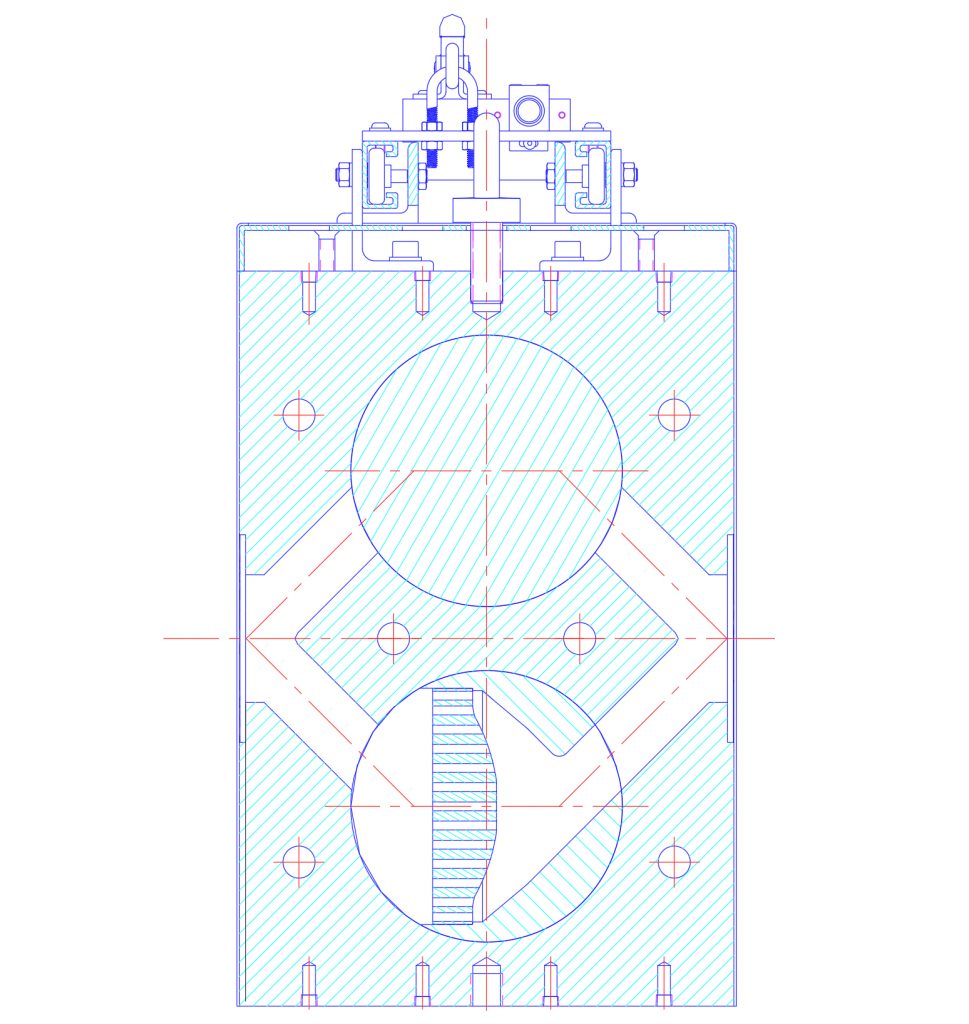

The polymer melt flow is divided into two streams at the housing inlet and is conveyed through each of the breaker plates and screen packs. Each breaker plate and flow channel is designed to accommodate the full throughput of the extruder or upstream equipment during a screen change. Entrained air is efficiently purged through vents before reintroduction of the screen pack.

Four (4) pocket models

For processes requiring increased filter area or desiring minimal pressure variation during a screen change, a four-pocket CSC continuous screen changer is recommended. The four pocket models reduce average pressure drop and in turn yield greater throughput. During momentary screen change, three screens are retained in flow. PLC stepper control minimizes pressure change at screen reentry and holds any change in flow rate during this process to little or none.

Specifications

| Temperature °F [°C] | Up to 650 [343] |

| Max oper. pressure PSI [bar] | max. 7,500 [500] |

| Control zones (housing) | One (1) or Two (2) |

| Heating | Electric/Fluid |

| Model | Max. Throughput* | Screen Diameter | Filter Area | Heater | Weight | ||||

| Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs | |

| CSC-058 | 375 | 170 | 2.3 | 58.3 | 2 x 4.1 | 2 x 26.7 | 6.0 | 316 | 143 |

| CSC-076 | 650 | 300 | 3.0 | 76.3 | 2 x 7.1 | 2 x 45.7 | 6.0 | 534 | 242 |

| CSC-096 | 1,000 | 450 | 3.8 | 96.3 | 2 x 11.3 | 2 x 72.8 | 6.0 | 534 | 242 |

| CSC-116 | 1,500 | 675 | 4.6 | 116.3 | 2 x 16.5 | 2 x 106.2 | 9.0 | 775 | 352 |

| CSC-125 | 1,800 | 825 | 4.9 | 125.3 | 2 x 19.1 | 2 x 123.3 | 9.0 | 1,100 | 499 |

| CSC-148 | 2,400 | 1,100 | 5.8 | 148.3 | 2 x 26.8 | 2 x 172.7 | 18.0 | 1,450 | 658 |

| CSC-176 | 3,500 | 1,600 | 6.9 | 176.3 | 2 x 37.8 | 2 x 244.1 | 18.0 | 2,645 | 1,200 |

| CSC-200 | 4,500 | 2,050 | 7.9 | 200.4 | 2 x 48.9 | 2 x 315.4 | 24.0 | 3,855 | 1,749 |

| CSC-230 | 6,000 | 2,700 | 9.1 | 230.3 | 2 x 64.6 | 2 x 416.5 | 36.0 | 4,200 | 1,906 |

| CSC-250 | 7,200 | 3,250 | 9.9 | 250.3 | 2 x 76.3 | 2 x 492.0 | 36.0 | 5,700 | 2,586 |

| CSC-300 | 10,500 | 4,750 | 11.8 | 300.3 | 2 x 109.8 | 2 x 708.3 | 108.0 | 9,200 | 4,174 |

| * Max. throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. * For 4-Pocket models multiply the estimated throughput by 2.5 - 3. Consult PSI for pressure drop. | |||||||||

| Model | Max. Throughput Rate* | Screen Oval | Filter Area | Heater | Weight | ||||

| Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs | |

| CSC-125/195 | 3,000 | 1,350 | 4.92 x 7.67 | 125 x 195 | 2 x 32.6 | 2 x 210.2 | |||

| CSC-148/230 | 4,100 | 1,850 | 5.71 x 9.06 | 148 x 230 | 2 x 45.5 | 2 x 293.4 | 18.0 | 1625 | 739 |

| CSC-176/270 | 5,800 | 2,600 | 6.87 x 10.63 | 175 x 270 | 2 x 63.1 | 2 x 406.8 | 24.0 | 2,750 | 1,248 |

| CSC-200/300 | 7,500 | 3,400 | 7.87 x 11.81 | 197 x 300 | 2 x 79.7 | 2 x 514.1 | 24.0 | 3,430 | 1,556 |

| CSC-230/310 | 9,000 | 4100 | 9.06 x 12.20 | 230 x 310 | 2 x 92.9 | 2 x 599.5 | 36.0 | 4,550 | 2,064 |

| CSC-250/345 | 12,000 | 5,500 | 9.84 x 13.58 | 250 x 345 | 2 x 112.9 | 2 x 728.3 | 72.0 | 7,745 | 3,514 |

| * Max. throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. * For 4-Pocket models multiply the estimated throughput by 2.5 - 3. Consult PSI for pressure drop. | |||||||||

Features

- Bi-flow design for uninterrupted flow

- No mechanical seals – 5-year leak-free guarantee

- No hang-up flow channels for fast material changes

- Oversize hydraulic cylinders

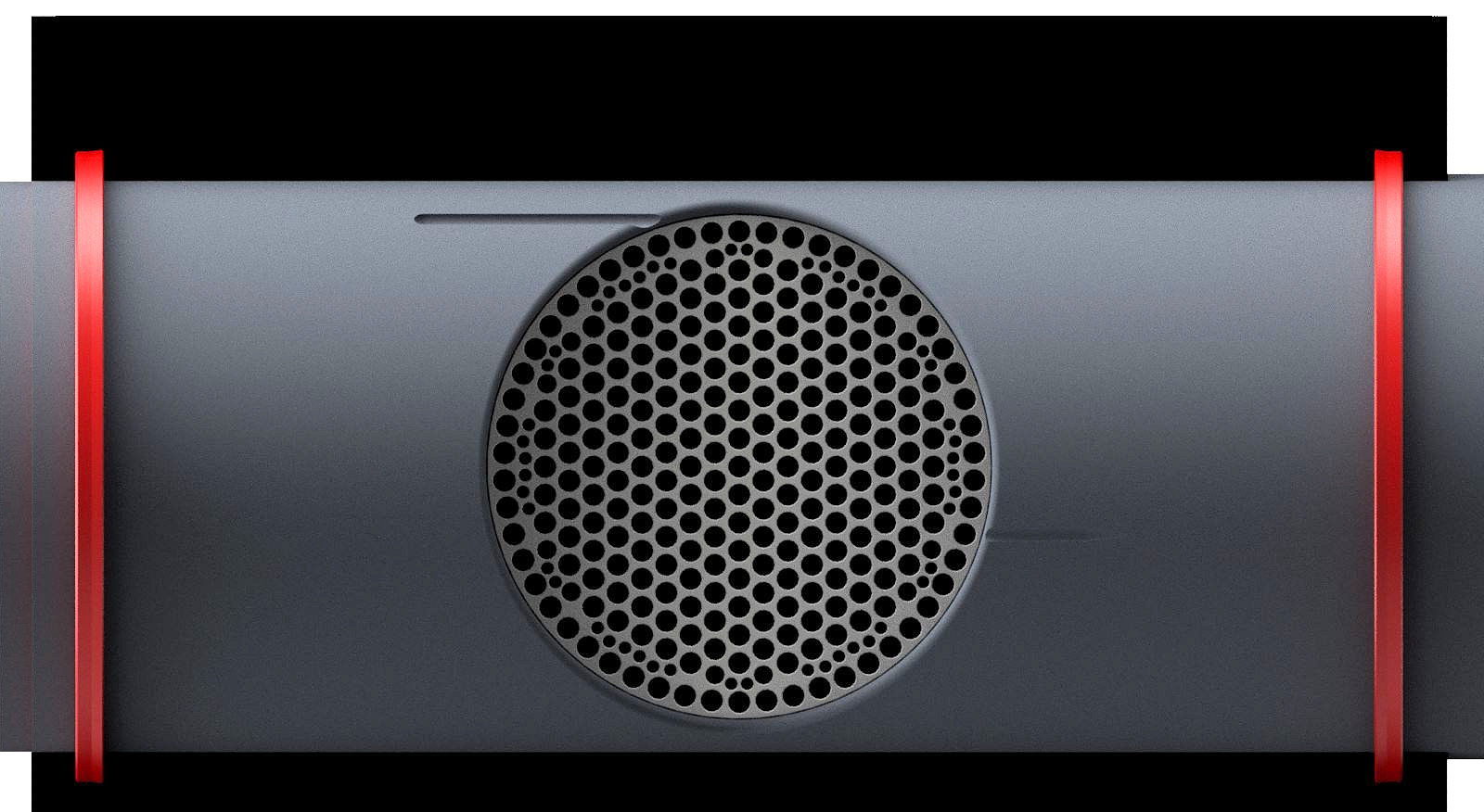

- 2 or 4 screen pocket designs

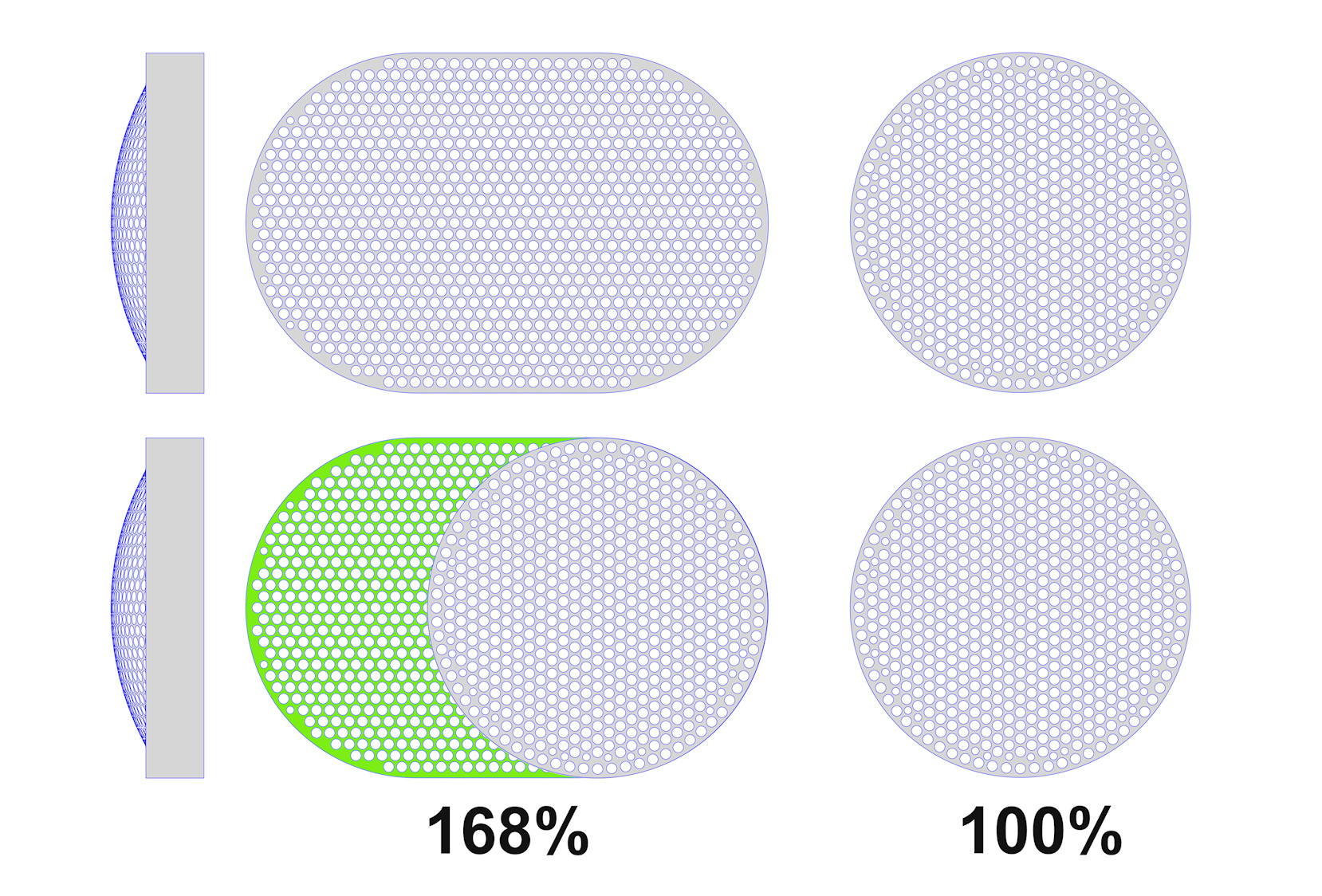

- Round or oval screen pockets

- Special patented seal for high melt-flow (1800 MFI) materials

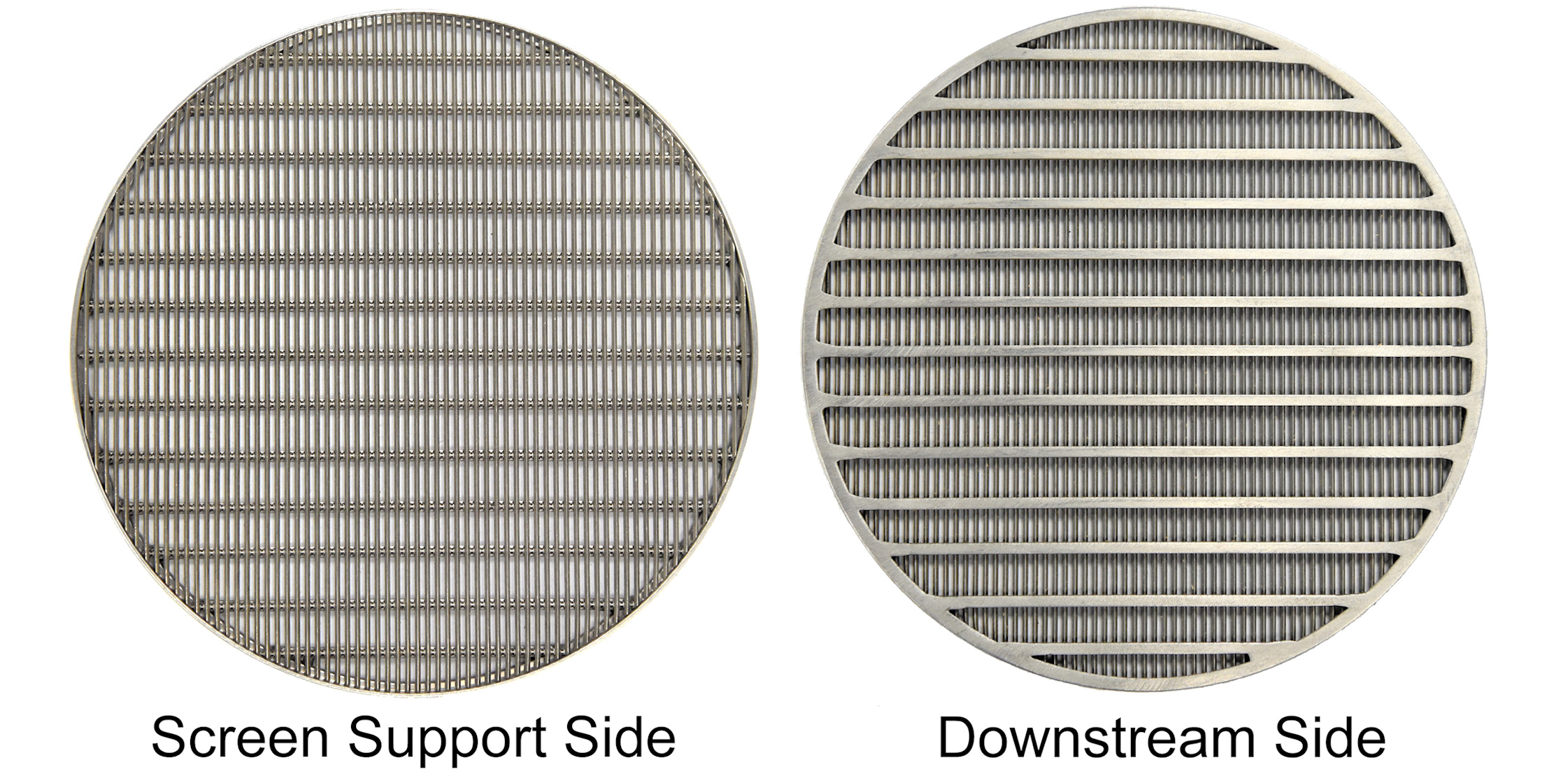

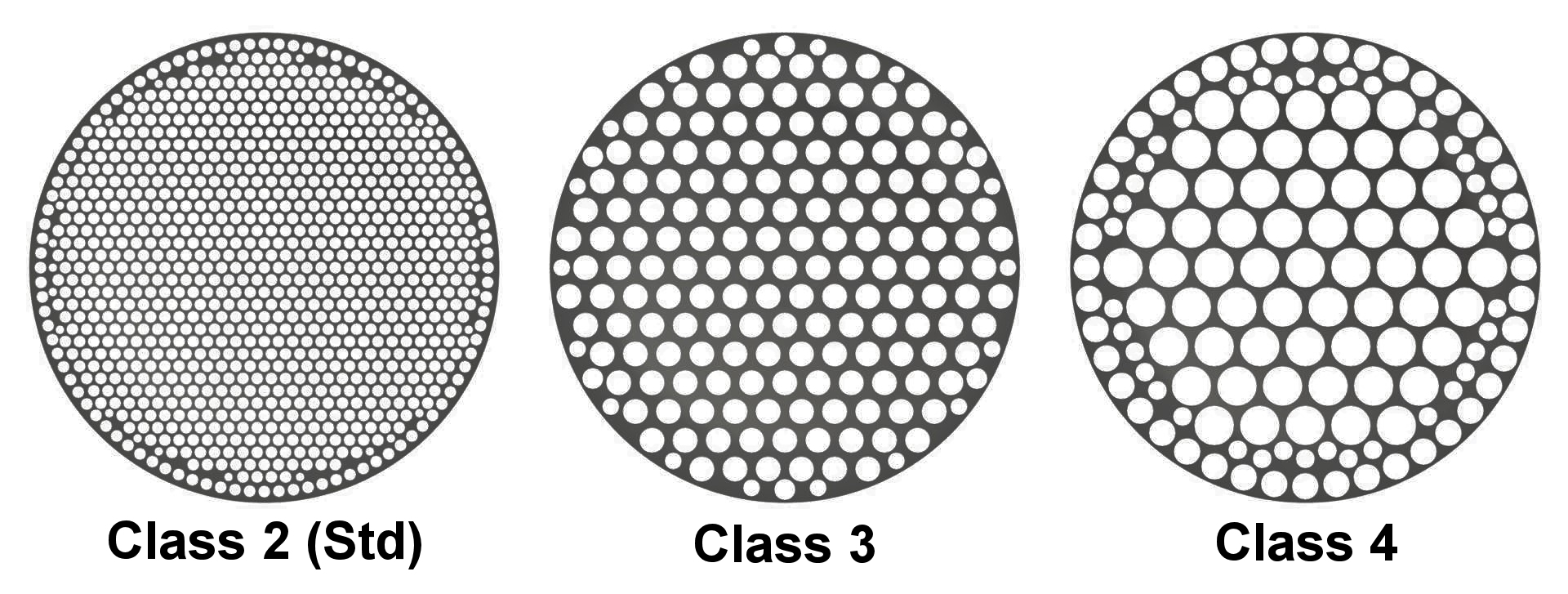

- Low restriction breaker plates with standard 1500 dP pressure rating. Optional high-strength breaker plates available for 3000 dP rating for high viscosity materials.

Options

Low Viscosity Seal

Special patented seal for ultra-low viscosity materials (click for info)

Oval Breaker Plates

Oval pockets add more filter area, lower delta-P, and more output (click for info)

Super Plates

Super plates for improved screen efficiency (click for info)

Low Delta-P

Larger breaker plate holes for pressure drop reduction (click for info)

Plus

- Application-specific materials of construction

- Application-specific clearances

- Vertical mount (up to CSC-176)

- Internal fluid heat/cool

- High temperature to 850°F [454°C]

- Special heater voltage

- Cart mounted Hydraulic Power Unit

Accessories

- Hydraulic Power Unit

- Support cart

- Adaptors

- Hot oil control units

- Manual hand-held pendant

- FilterPak PLC: Control for one screen changer (micro or full PLC platforms)

- IntegraPak PLC: Integrated control for screen changer, pump, downstream haul-off and heat zones

- Stand-alone Heat Control Panel