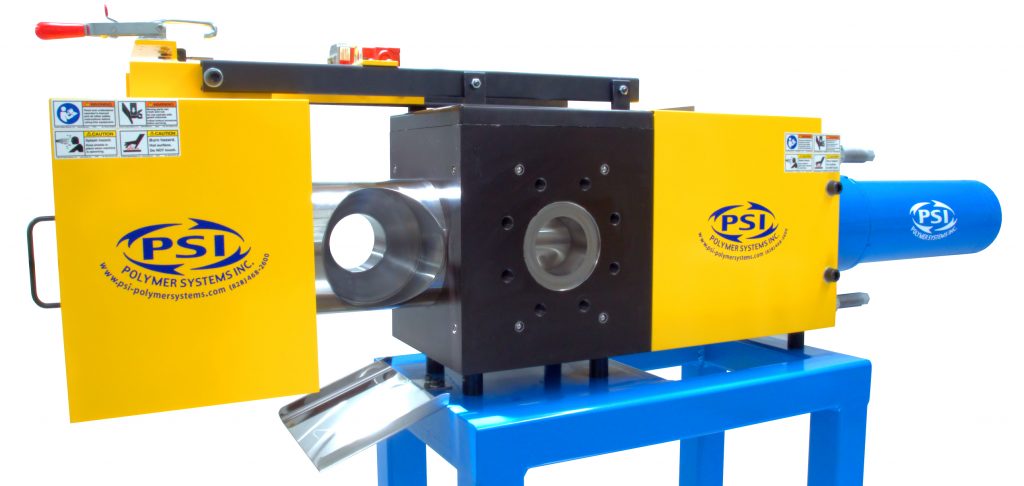

Discontinuous Screen Changer (DSC)

Get More from Your Process

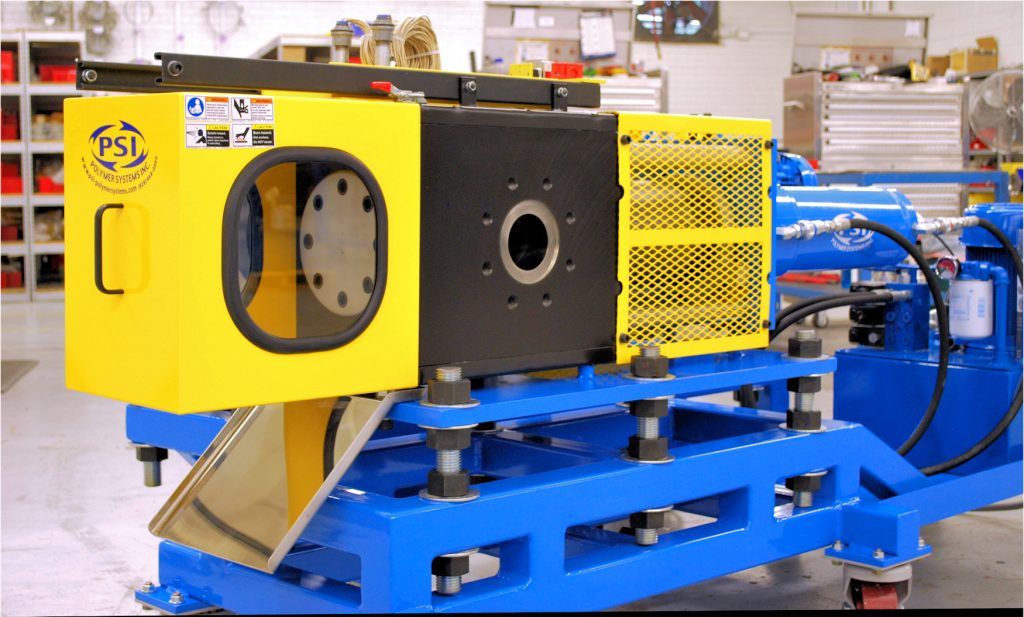

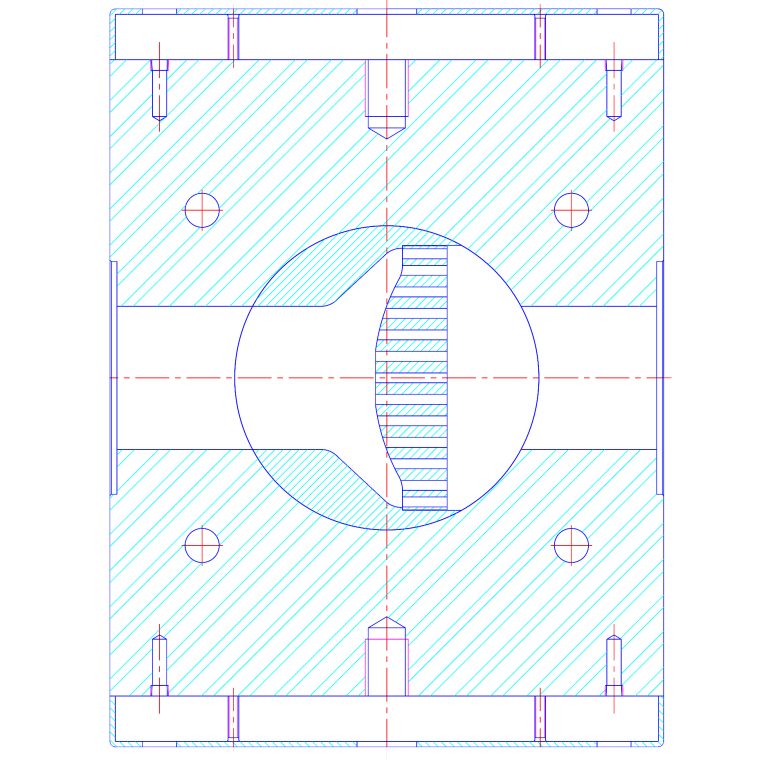

The Discontinuous Screen Changer (DSC) provides convenient, easy access melt filtration for polymer and hot melt adhesive batch operations. The design features a single filter pocket machined into a cross-bolt. Shifted offline only for momentary screen change, the easy-to-clean filter pocket has no hang-up areas and features a streamlined flow channel for fast material or color changes without cross-contamination. The self-sealing design has no mechanical parts to wear out or replace. Maintenance is reduced to periodic cleaning of the cross-bolt.

An optional patented seal insert allows the Discontinuous Screen Changer to filter materials with viscosities as low as 10 centipoise / 1800 MFI without risk of leakage. The design can also accommodate an integral divert for batch operation startup or changeover.

Specifications

| Temperature °F [°C] | Up to 600 [315] |

| Max oper. pressure PSI [bar] | max. 7,500 [517] |

| Control zones (housing) | One (1) |

| Heating | Electric |

| Round Screen | Max. Throughput* | Screen Diameter | Filter Area | Heater | Weight | ||||

| Model | Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs |

| DSC-058 | 375 | 170 | 2.3 | 58.3 | 4.1 | 26.7 | 2.0 | 150 | 68 |

| DSC-076 | 650 | 295 | 3.0 | 76.3 | 7.1 | 45.7 | 4.0 | 267 | 121 |

| DSC-096 | 1,000 | 455 | 3.8 | 96.3 | 11.3 | 72.8 | 4.0 | 266 | 121 |

| DSC-116 | 1,500 | 680 | 4.6 | 116.3 | 16.5 | 106.2 | 4.0 | 415 | 188 |

| DSC-125 | 1,800 | 910 | 4.9 | 125.3 | 19.1 | 123.3 | 6.0 | 477 | 216 |

| DSC-148 | 2,400 | 1,090 | 5.8 | 148.3 | 26.8 | 172.7 | 12.0 | 1,325 | 601 |

| DSC-176 | 3,500 | 1,590 | 6.9 | 176.3 | 37.8 | 244.1 | 12.0 | 1,335 | 606 |

| DSC-200 | 4,500 | 2,040 | 7.9 | 200.4 | 48.9 | 315.4 | 24.0 | 2,025 | 919 |

| DSC-230 | 6,000 | 2,720 | 9.1 | 230.3 | 64.6 | 416.5 | 24.0 | 2,912 | 1,321 |

| DSC-250 | 8,000 | 3,630 | 9.9 | 250.3 | 76.3 | 492.0 | 24.0 | 3,250 | 1,597 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||

| Oval Screen | Max. Throughput* | Screen Diameter | Filter Area | Heater | Weight | ||||

| Model | Lbs/Hr | Kg/Hr | Inches | mm | Inches² | cm² | kW | lbs | kgs |

| DSC-125/170 | 2,500 | 1,090 | 4.92 x 6.69 | 125 x 170 | 27.7 | 179.0 | 6.0 | 850 | 386 |

| DSC-148/230 | 4,100 | 1,500 | 5.71 x 9.06 | 145 x 230 | 44.7 | 288.4 | 12.0 | 1,325 | 601 |

| DSC-176/270 | 5,800 | 2,585 | 6.87 x 10.63 | 175 x 270 | 63.1 | 406.8 | 18.0 | 1,090 | 495 |

| DSC-200/300 | 7,500 | 4,400 | 7.87 x 11.81 | 197 x 300 | 79.7 | 514.1 | 24.0 | 2,695 | 1,223 |

| DSC-230/310 | 9,000 | 5,990 | 9.06 x 12.20 | 230 x 310 | 92.9 | 599.5 | 24.0 | 3,580 | 1,624 |

| DSC-250/345 | 12,000 | 9,980 | 9.84 x 13.58 | 250 x 345 | 112.9 | 728.3 | 24.0 | 3,580 | 1,624 |

| * Throughput rates are estimates and are subject to material, viscosity, pressure, and filtration level. | |||||||||

Features

- Single filter pocket for batch operations

- Self-sealing cross-bolt design – 5-year leak-free guarantee

- Mechanical stop for accurate positioning

- No cross-contamination for color changes

- Large, robust hydraulic cylinder for added shift assurance

- Hand-held pendant control

- Safety guards / Fully guarded for operator safety / Safety guard with electrical interlock

- Insulated top and bottom covers for operator safety

- Field interchangeability of pistons, bolts, and housings

Options

Low Viscosity Seal

Special patented seal for ultra-low viscosity materials (click for info)

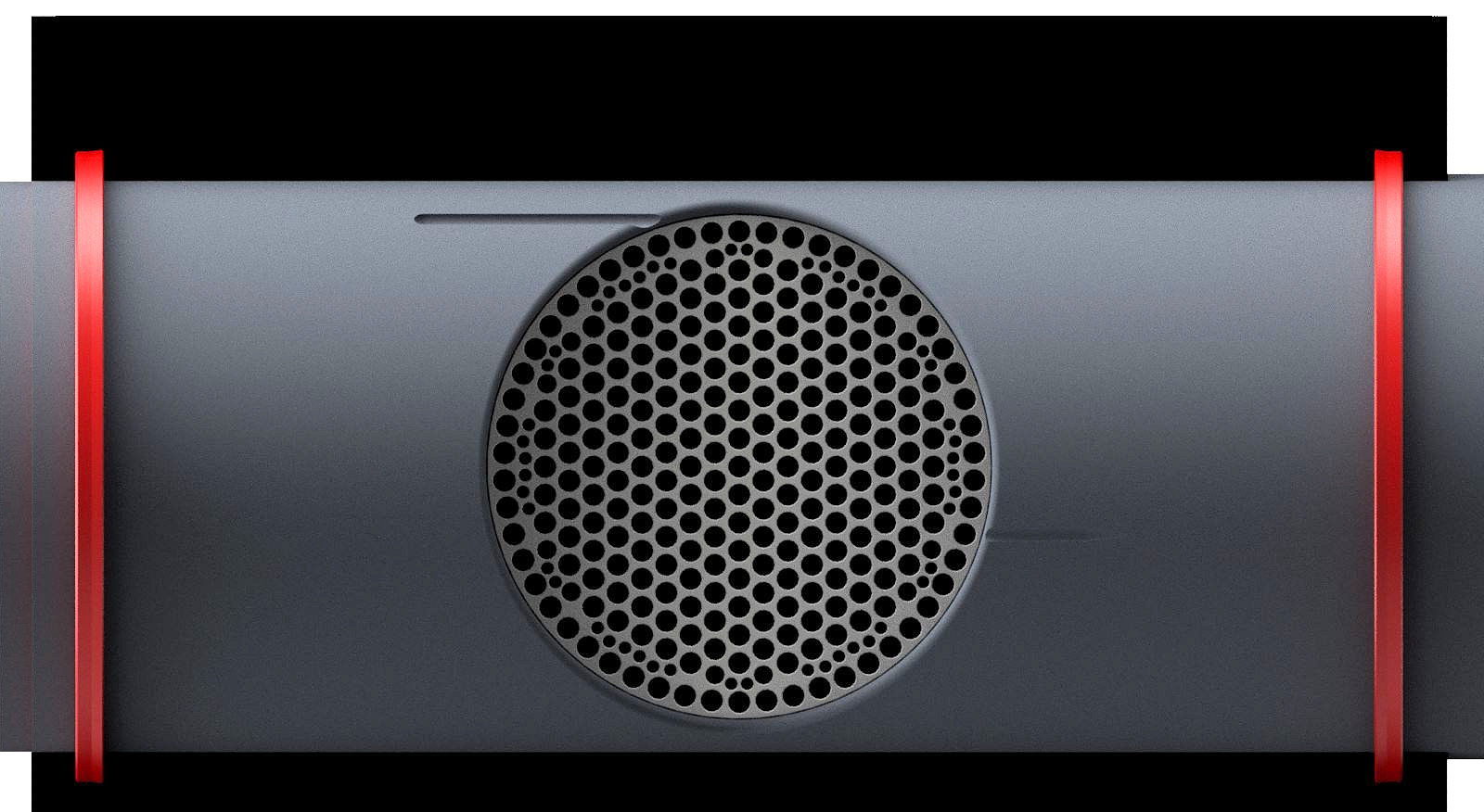

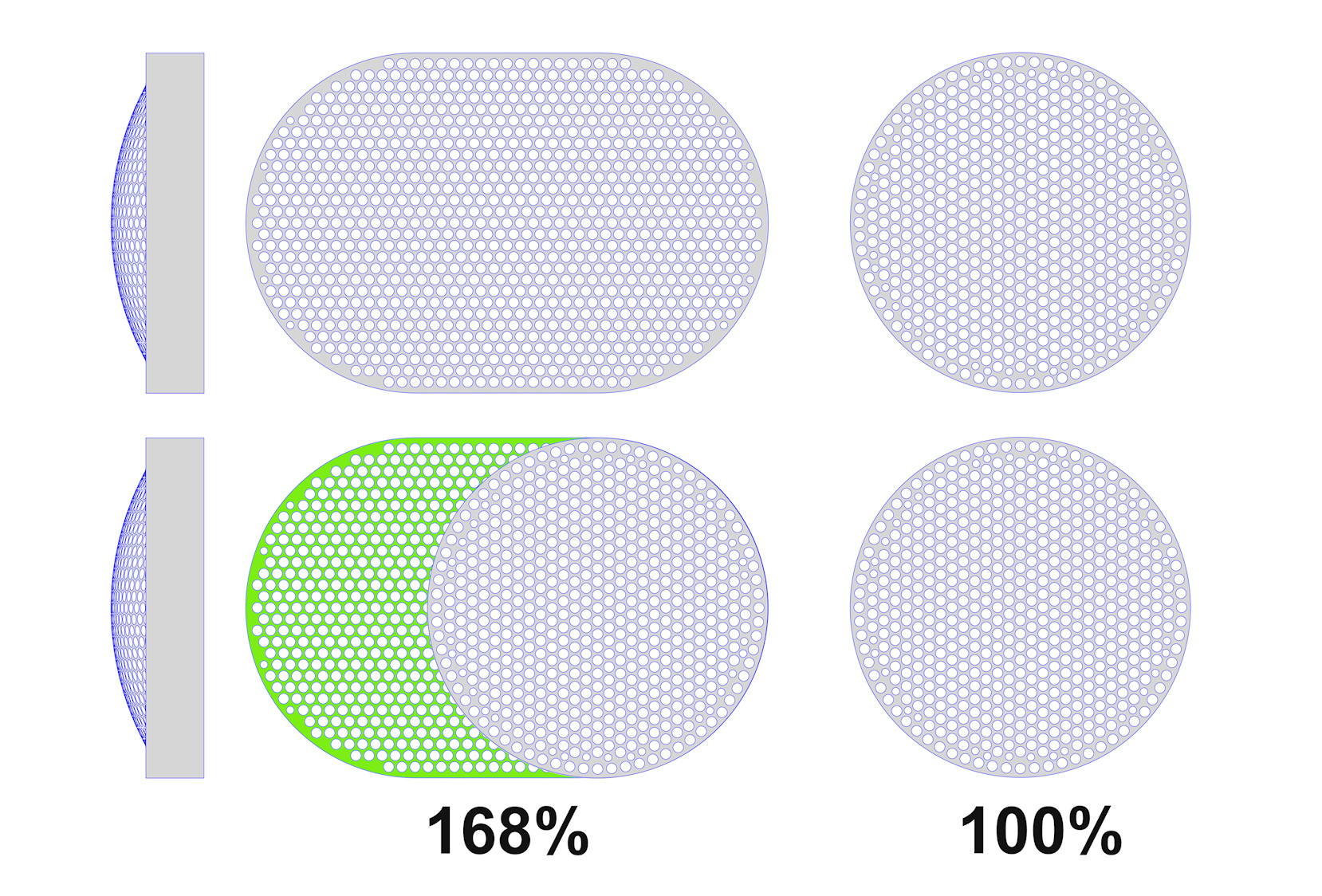

Oval Breaker Plates

Oval pockets add more filter area, lower delta-P, and more output (click for info)

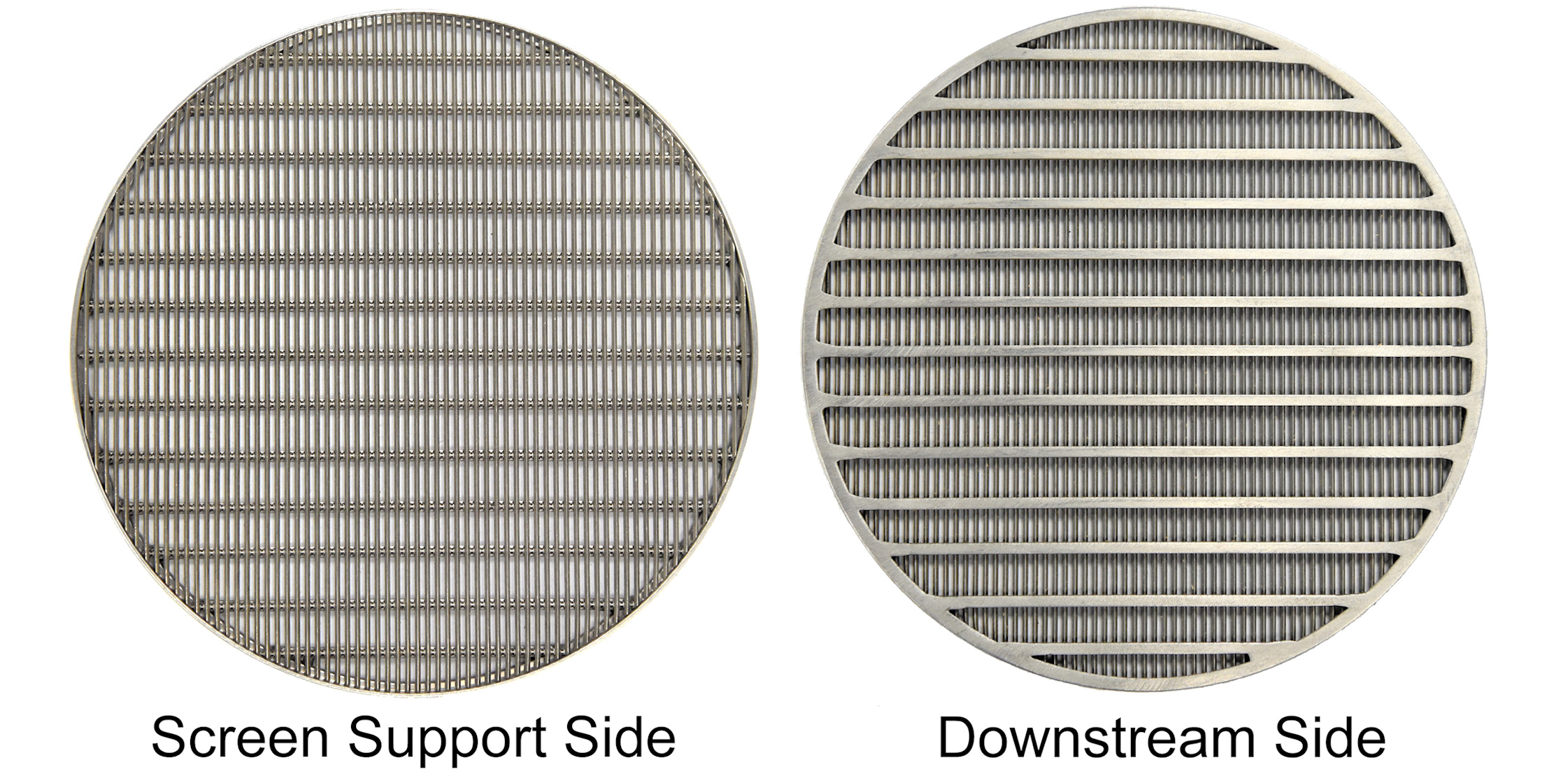

Super Plates

Super plates for improved screen efficiency (click for info)

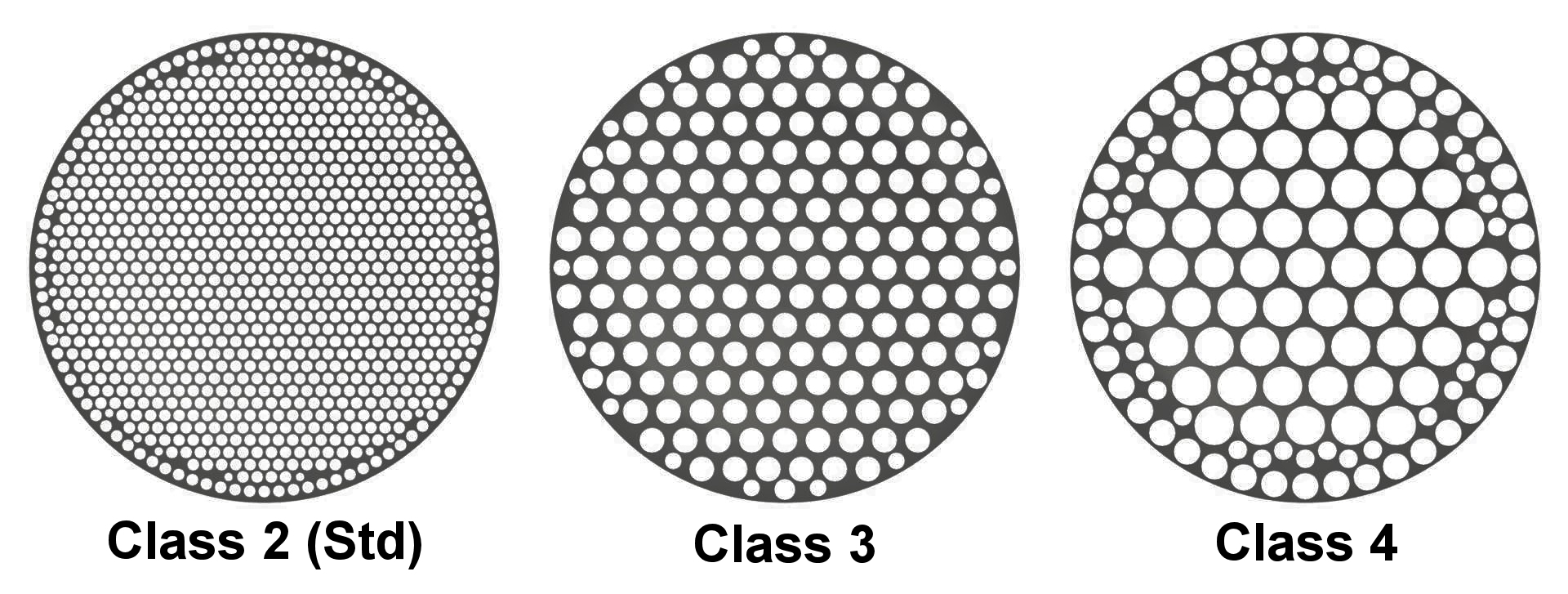

Low Delta-P

Larger breaker plate holes for pressure drop reduction (click for info)

Plus

- Application-specific clearances

- Application-specific materials of construction

- Plating

- Hydraulic cylinder proximity sensors or linear transducer

- Integrated divert position

- High-pressure, low delta-P breaker plates

- Internal fluid heat/cool

- Insulation jackets

- Vertical orientation (up to DSC-230)

- HPU manifold for multi-unit operation

- Special voltage heaters

- Transducer port

Accessories

- Hydraulic Power Unit

- Support cart

- Drip tray to capture drool material

- Adaptors

- Pressure instruments

- Hot oil control units

- Manual hand-held pendant

- Stand-alone Heat Control Panel